Complete off-grid solar technology systems represent a transformative solution for businesses seeking energy independence and operational resilience. These autonomous power systems, combining solar panels, battery storage, inverters, and sophisticated control systems, enable facilities to operate entirely independent of traditional utility grids while maintaining reliable 24/7 power supply.

For forward-thinking organizations, complete off-grid solar installations deliver three critical advantages: elimination of utility costs, protection against grid-related disruptions, and significant reduction in carbon emissions. Modern systems achieve 99.9% reliability through advanced energy management algorithms, redundant storage solutions, and intelligent load management capabilities.

Recent advancements in battery technology and solar panel efficiency have made these systems increasingly viable for commercial applications, with ROI periods averaging 5-7 years for properly sized installations. Industry leaders implementing complete off-grid solutions report 40-60% reductions in total energy costs while maintaining uninterrupted operations during extreme weather events and grid failures.

As global supply chains evolve and energy security becomes paramount, complete off-grid solar systems emerge as a strategic asset for businesses seeking operational resilience and sustainable growth. These systems represent not just an energy solution, but a comprehensive approach to business continuity and environmental stewardship.

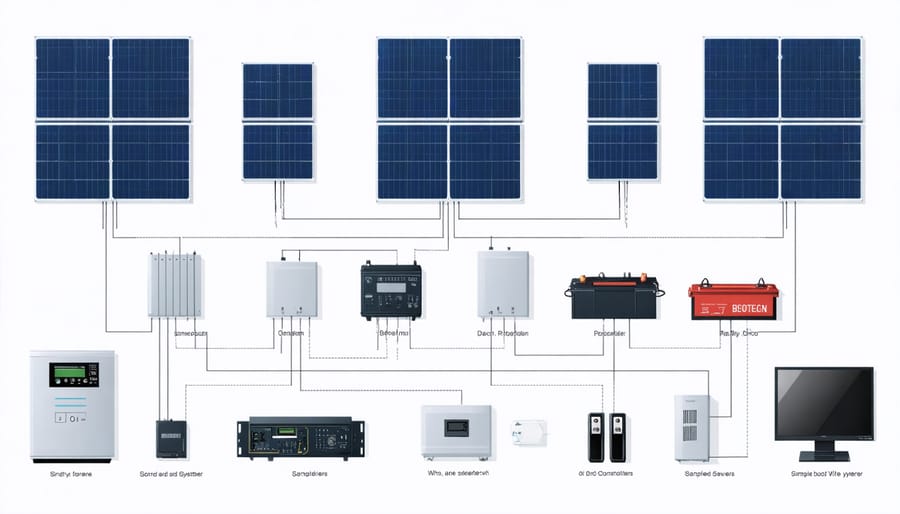

Components of a Complete Off-Grid Solar System

Solar Panels and Module Sourcing

When selecting solar panels for off-grid systems, quality and reliability are paramount considerations. Tier-1 manufacturers like SunPower, LG, and Canadian Solar offer high-efficiency monocrystalline panels with proven track records in durability and performance. These panels typically provide 15-25% efficiency rates and come with 25-year warranties, ensuring long-term value for your investment.

Supply chain considerations have become increasingly critical in recent years. Working with established distributors who maintain strong relationships with multiple manufacturers can help mitigate delivery delays and price fluctuations. While financing solar installations is important, securing a reliable panel supply should be equally prioritized.

For off-grid applications, bifacial panels are gaining popularity due to their ability to capture reflected light, potentially increasing energy yield by 5-30% in suitable environments. Premium panels with enhanced durability features, such as split-cell technology and reinforced frames, offer better resistance to extreme weather conditions and reduced degradation rates, making them ideal for remote installations where maintenance access may be limited.

Battery Storage Solutions

Battery storage is a critical component of off-grid solar systems, requiring careful consideration of both technology selection and supply chain management. Lithium-ion batteries have emerged as the industry standard, offering superior energy density, longer cycle life, and reduced maintenance requirements compared to traditional lead-acid alternatives. For commercial installations, the Tesla Powerwall and LG Chem RESU series demonstrate exceptional performance metrics, with round-trip efficiencies exceeding 90%.

To ensure reliable battery supply, organizations should develop relationships with multiple tier-1 manufacturers and maintain strategic inventory levels. Implementation of smart battery management systems (BMS) helps optimize performance and extend battery life through real-time monitoring and predictive maintenance protocols.

Recent developments in solid-state battery technology and flow batteries show promise for future applications, potentially offering even greater energy density and longer operational lifespans. When selecting battery solutions, consider factors such as depth of discharge (DoD), temperature tolerance, and warranty terms. A typical commercial installation requires 2-3 days of autonomy, necessitating careful capacity planning based on peak load requirements and seasonal variations in solar generation.

Storage systems should be housed in climate-controlled environments and integrated with advanced monitoring systems to maintain optimal operating conditions and ensure maximum return on investment.

Inverters and Control Systems

Inverters and control systems serve as the operational backbone of off-grid solar installations, converting DC power from solar panels into usable AC power while managing system performance. High-quality inverters typically represent 15-20% of total system costs but are crucial for reliable operation. When sourcing these components, prioritize manufacturers with proven track records in off-grid applications and comprehensive warranty coverage.

Modern control systems integrate advanced monitoring capabilities, allowing remote system management and performance optimization. Key features to consider include automatic load management, battery state monitoring, and smart switching between power sources. For enterprise-scale installations, hybrid inverters with built-in charge controllers offer streamlined procurement and simplified system architecture.

Procurement strategies should focus on establishing relationships with authorized distributors who can provide ongoing technical support and guarantee component compatibility. Consider future expansion requirements when selecting inverter capacity to avoid costly system upgrades.

Supply Chain Optimization Strategies

Supplier Diversification

In today’s dynamic solar energy market, implementing effective supply chain optimization through supplier diversification is crucial for maintaining system reliability and cost efficiency. Successful off-grid solar installations require establishing relationships with multiple qualified suppliers for key components, including solar panels, batteries, inverters, and control systems.

Leading organizations typically maintain partnerships with 2-3 primary suppliers for each critical component, complemented by relationships with secondary suppliers who can fulfill orders during supply disruptions. This approach ensures continuous access to essential materials while maintaining competitive pricing structures.

When selecting suppliers, consider factors such as manufacturing capacity, quality certifications, warranty terms, and geographical location. Engaging with suppliers from different regions helps mitigate risks associated with regional economic fluctuations, natural disasters, or geopolitical events.

Implementing a supplier rating system based on delivery performance, product quality, and technical support capabilities enables systematic evaluation and relationship management. Regular supplier audits and performance reviews help maintain quality standards and identify potential risks before they impact operations.

Digital procurement platforms and inventory management systems can streamline the supplier diversification process, providing real-time visibility into supply chain performance and enabling quick responses to potential disruptions. This technology-driven approach, combined with strategic supplier relationships, creates a resilient supply network for off-grid solar systems.

Quality Control Protocols

Quality control in off-grid solar systems requires a comprehensive approach across multiple checkpoints throughout the supply chain. Leading manufacturers implement rigorous testing protocols, including flash testing for solar panels, capacity verification for batteries, and performance validation for inverters under various load conditions.

Component certification plays a vital role, with industry standards such as IEC 61215 for solar modules and UL 1741 for inverters serving as baseline requirements. Reputable suppliers maintain detailed documentation of testing procedures and results, ensuring traceability and accountability throughout the supply chain.

On-site inspection protocols typically involve three crucial phases: incoming component verification, installation quality assessment, and system commissioning. During the receiving process, components undergo thorough visual inspections and performance testing to identify any shipping damage or manufacturing defects.

Environmental stress testing has become increasingly important, particularly for systems deployed in extreme conditions. Components must demonstrate resilience against temperature fluctuations, humidity, salt spray, and mechanical stress. Many manufacturers now utilize accelerated life testing to simulate years of environmental exposure within compressed timeframes.

Quality management systems (QMS) based on ISO 9001 standards help maintain consistent quality across manufacturing and assembly processes. Regular supplier audits, combined with performance monitoring and data analysis, enable continuous improvement in component reliability and system performance. This systematic approach to quality control helps ensure the longevity and reliability of off-grid solar installations while minimizing maintenance requirements and operational disruptions.

Inventory Management

Effective inventory management is crucial for maintaining reliable off-grid solar system operations. Successful implementation requires strategic planning of stock levels for critical components, including solar panels, batteries, inverters, and backup parts. Industry best practices recommend maintaining a minimum 30-day supply of essential replacement parts and consumables.

For optimal inventory control, implement a digital tracking system that monitors component usage patterns and automatically triggers reorder points. This system should account for lead times, which can vary significantly for specialized solar equipment. Establish relationships with multiple suppliers to ensure consistent availability and competitive pricing while mitigating supply chain risks.

Critical components requiring careful stock management include:

– Battery banks and individual cells

– Charge controllers

– Inverter components

– Solar panel replacements

– Connection hardware and wiring

– Monitoring system components

Consider environmental factors when determining storage requirements. Temperature-controlled facilities are essential for batteries and sensitive electronic components. Maintain detailed documentation of component specifications, warranties, and maintenance schedules to anticipate replacement needs accurately.

Regular inventory audits, typically conducted quarterly, help identify slow-moving items and potential supply gaps. Implement a first-in-first-out (FIFO) rotation system for components with limited shelf life. For remote installations, consider establishing regional supply hubs to reduce response times for critical maintenance needs.

Develop contingency plans for supply chain disruptions by identifying alternative suppliers and maintaining emergency stock levels for mission-critical components. This approach ensures system reliability while optimizing working capital investment.

Installation and Integration Considerations

Project Planning and Timing

Successful implementation of off-grid solar systems requires meticulous planning and precise timing coordination. The delivery and installation schedule should align with site preparation, weather conditions, and resource availability. Project managers must consider seasonal variations that could impact installation efficiency, particularly in remote locations where access might be limited.

Component procurement typically requires 8-12 weeks lead time, with specialized equipment potentially extending this timeline. Critical components like batteries and inverters often have longer manufacturing and shipping schedules, which must be factored into the project timeline. For larger installations, including hybrid power systems, coordinating multiple suppliers demands careful synchronization to prevent costly delays.

A well-structured installation schedule should allocate adequate time for:

– Site preparation and foundation work (1-2 weeks)

– Mounting system installation (3-5 days)

– Solar panel placement (5-7 days)

– Battery bank setup (2-3 days)

– Inverter and control system installation (2-3 days)

– System testing and commissioning (3-4 days)

It’s essential to build in contingency time for unexpected delays and maintain clear communication channels with all stakeholders throughout the project lifecycle. Regular progress meetings and detailed documentation help ensure smooth coordination between contractors, suppliers, and technical teams.

Installation Partner Network

A robust installation partner network is crucial for the successful deployment of complete off-grid solar systems. Leading manufacturers and suppliers typically maintain relationships with certified installers across various regions, ensuring consistent quality and reliability in system implementation.

These partnerships often involve rigorous vetting processes, including verification of technical expertise, safety protocols, and track record in solar installations. Partners must demonstrate proficiency in both electrical systems and structural engineering, as off-grid installations require specialized knowledge of battery storage, inverter systems, and load management.

Quality assurance programs typically include regular training sessions, certification updates, and performance monitoring. Installation partners receive ongoing support through technical documentation, design assistance, and emergency response protocols. This collaborative approach helps maintain high standards while reducing installation risks and potential system failures.

Many successful networks implement a tiered partnership structure, where installers can progress through levels based on experience, volume, and customer satisfaction ratings. This creates incentives for continuous improvement and professional development within the network.

Regional coverage is another critical factor, with networks strategically distributed to ensure prompt service delivery and maintenance support. Partners often maintain local inventory of critical components and spare parts, enabling faster response times for both installations and repairs. This distributed approach strengthens the overall reliability of off-grid solar solutions while supporting local economic development through job creation and skills transfer.

Maintenance and Support Infrastructure

Spare Parts Management

Effective spare parts management is crucial for maintaining the reliability of off-grid solar systems. A strategic inventory of critical components helps minimize system downtime and ensures continuous operation, particularly in remote locations where replacement parts may not be readily available.

Essential components to maintain in inventory include solar panel replacements (typically 2-3% of total installation), charge controllers, inverter components, and battery cells. For battery banks, keeping at least one complete battery unit as a backup is recommended, along with maintenance materials such as distilled water and terminal cleaners for flooded lead-acid batteries.

Implement a tiered inventory system based on component criticality and lead times. Track usage patterns and establish minimum stock levels with automated reorder points. Store spare parts in climate-controlled environments to prevent degradation, particularly for electronic components and batteries.

Develop relationships with multiple suppliers to ensure reliable access to replacement parts. Consider establishing service level agreements (SLAs) with key suppliers for critical components. Maintain detailed documentation of all spare parts, including serial numbers, warranty information, and maintenance history.

Regular inventory audits help identify slow-moving items and optimize stock levels. Consider participating in spare parts sharing programs with other facilities in your region to reduce inventory costs while maintaining access to critical components. This collaborative approach can significantly reduce carrying costs while ensuring system reliability.

Service Network Development

Establishing a robust service provider network is crucial for the long-term success of off-grid solar installations. The process begins with identifying and vetting qualified local solar installers, maintenance technicians, and equipment suppliers who have demonstrated expertise in off-grid systems.

Key partnerships should include certified solar contractors, electrical engineers, and component manufacturers who can provide warranty support and replacement parts. These relationships ensure quick response times for maintenance issues and minimize system downtime. Regular training programs and certification updates for service providers help maintain high service standards and keep technicians current with evolving technology.

Documentation of service provider capabilities, response times, and performance metrics helps optimize network reliability. Creating service level agreements (SLAs) with clear performance indicators and response time requirements ensures accountability and consistent service quality.

Geographic coverage is another critical consideration. Strategic partnerships with providers across different regions can ensure comprehensive service coverage, especially for remote installations. Implementing a digital service management system can streamline maintenance scheduling, track service history, and coordinate emergency responses effectively.

Regular evaluation of service provider performance, customer feedback, and network capacity helps identify areas for improvement and expansion. This ongoing assessment ensures the service network evolves with growing system demands and technological advancements, maintaining optimal system performance throughout its lifecycle.

Preventive Maintenance Programs

A robust preventive maintenance program is essential for maximizing the longevity and performance of off-grid solar systems. Regular maintenance schedules should include quarterly inspections of solar panels, battery banks, and inverters, along with annual comprehensive system assessments. These inspections help identify potential issues before they escalate into costly repairs or system failures.

Key maintenance activities include cleaning solar panels to maintain optimal energy production, checking battery fluid levels and connections, testing inverter functionality, and inspecting all electrical connections. Documentation of these activities through digital maintenance logs enables trend analysis and predictive maintenance planning.

Supply chain support is crucial for maintaining system reliability. Establish relationships with multiple component suppliers and maintain an inventory of critical spare parts on-site. This approach minimizes downtime during replacements or repairs. Consider implementing inventory management systems that track part usage and automatically trigger reorders when stock reaches predetermined levels.

For remote installations, develop partnerships with local service providers who can respond quickly to maintenance needs. Training facility staff in basic maintenance procedures also helps ensure immediate response to common issues. Many modern off-grid systems include remote monitoring capabilities, allowing for real-time performance tracking and early problem detection.

Regular evaluation of maintenance protocols helps optimize procedures and reduce operational costs while ensuring system reliability. This proactive approach typically results in a 15-20% increase in system lifespan and maintains peak performance levels.

As the global demand for reliable off-grid power solutions continues to grow, the supply chain landscape for complete solar systems is evolving rapidly. Industry trends indicate a steady improvement in component availability, manufacturing efficiency, and distribution networks, making sustainable energy solutions more accessible than ever before.

The success of off-grid solar implementations depends heavily on robust supply chain management, from initial procurement to long-term maintenance support. Organizations that have established strong relationships with reliable suppliers and maintained comprehensive inventory management systems have demonstrated superior project outcomes and operational efficiency.

Looking ahead, several key developments are expected to shape the future of off-grid solar supply chains. Advanced battery technologies, improved solar panel efficiency, and smart energy management systems will continue to drive innovation. The integration of artificial intelligence and IoT capabilities will enhance system monitoring and predictive maintenance, reducing operational costs and improving reliability.

Supply chain resilience will remain crucial, with diversified sourcing strategies and local manufacturing capabilities gaining importance. The trend toward standardization of components and installation procedures will facilitate easier maintenance and replacements, while also reducing overall system costs.

For businesses and organizations considering off-grid solar installations, the timing has never been better. With established supply networks, proven technologies, and increasing cost-effectiveness, complete off-grid solar systems represent a viable and sustainable power solution for diverse applications. Success in implementation will depend on careful planning, strategic supplier selection, and commitment to ongoing system optimization and maintenance.