Transforming warehouse operations with solar power represents one of the most significant opportunities for businesses to reduce operational costs while advancing environmental sustainability. As energy demands continue to rise and electricity prices surge, forward-thinking companies are leveraging their vast roof spaces to generate clean, renewable energy that can power everything from lighting and HVAC systems to automated equipment and electric forklifts. Recent industry data reveals that solar-powered warehouses can reduce energy costs by up to 75% while providing a return on investment within 5-7 years.

The convergence of declining solar panel costs, improved energy storage solutions, and generous government incentives has created an optimal environment for warehouse solar adoption. Major retailers and logistics companies are leading this transformation, with companies like Amazon and Walmart deploying massive rooftop solar installations across their distribution networks. These initiatives not only demonstrate environmental leadership but also provide a compelling business case for facilities of all sizes to embrace solar power.

Whether managing a single facility or overseeing a nationwide network of distribution centers, understanding the potential of solar power to revolutionize warehouse operations has become essential for modern facility managers and business leaders committed to sustainable, cost-effective operations.

The Business Case for Solar-Powered Warehouses

Energy Cost Reduction Potential

The implementation of solar power systems in warehouses presents substantial cost-reduction opportunities, with typical ROI for commercial solar installations ranging from 3 to 7 years. Based on current market analysis, warehouses can expect to reduce their energy costs by 40-80%, depending on facility size and energy consumption patterns.

A 100,000-square-foot warehouse typically requires a 250-300kW solar system, which can generate annual savings of $45,000-$60,000 in electricity costs. When factoring in federal tax incentives, depreciation benefits, and state-specific rebates, the initial investment can often be offset within 4-5 years.

The cost-reduction potential becomes even more significant when considering peak demand charges. Solar installations equipped with battery storage systems can reduce these charges by up to 50%, offering additional savings of $15,000-$25,000 annually for large warehouses.

Maintenance costs for solar systems remain minimal, typically averaging just 1-2% of the initial investment annually. This translates to predictable operating expenses and enhanced budget control. Furthermore, facilities implementing solar power systems often experience increased property values, with studies indicating a 3-5% appreciation in commercial property values following solar installation.

With electricity rates continuing to rise at approximately 2-3% annually, the long-term financial benefits of solar power become increasingly attractive for warehouse operations.

Available Tax Incentives and Grants

Businesses implementing solar power solutions for their warehouses can access numerous financial incentives for solar installations at federal, state, and local levels. The federal Investment Tax Credit (ITC) remains one of the most significant benefits, allowing businesses to deduct up to 30% of their solar installation costs from their federal taxes through 2032.

Many states offer additional tax incentives, including property tax exemptions for the added value of solar installations and sales tax exemptions on solar equipment purchases. Performance-based incentives (PBIs) and Solar Renewable Energy Certificates (SRECs) provide ongoing revenue streams based on the amount of energy your system generates.

Commercial warehouse operators can also benefit from accelerated depreciation through the Modified Accelerated Cost Recovery System (MACRS), allowing them to depreciate their solar assets over just five years. Local utility companies often provide rebates and grants for commercial solar installations, which can significantly reduce initial costs.

Some regions offer specialized programs for industrial-scale installations, such as feed-in tariffs or net metering arrangements, allowing businesses to sell excess power back to the grid. Additionally, various environmental improvement funds and sustainable development grants are available through state-level organizations and private institutions, particularly for warehouses implementing comprehensive energy efficiency measures alongside solar installations.

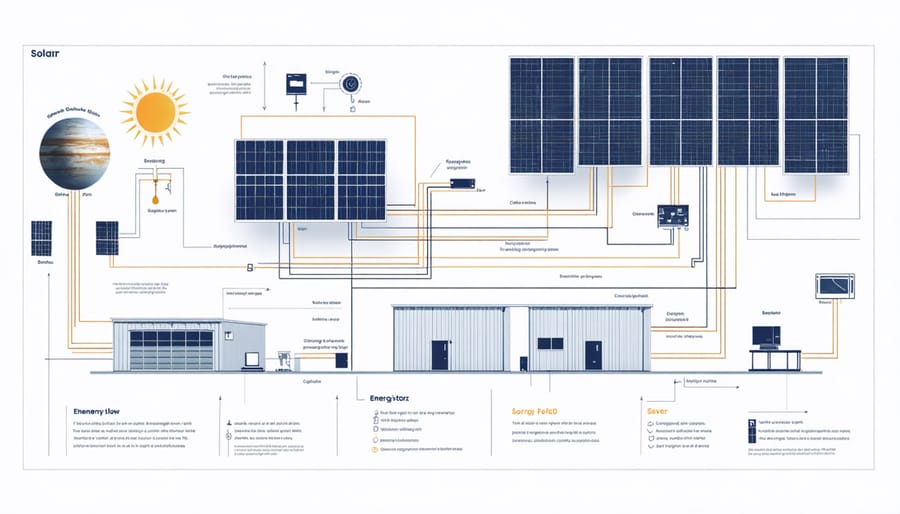

Key Components of a Warehouse Solar System

Rooftop Solar Array Design

The rooftop solar array design for warehouse facilities requires careful consideration of both layout optimization and structural integrity. Panels are typically arranged in east-west or south-facing configurations, with the specific orientation determined by the facility’s geographical location and roof characteristics. Most warehouse rooftops can accommodate 10-15 watts per square foot of solar panels, making them ideal candidates for large-scale installations.

Structural considerations include roof load capacity, which must support both the solar array’s weight (typically 2-4 pounds per square foot) and environmental factors such as snow and wind loads. Modern mounting systems utilize ballasted or mechanically attached solutions, minimizing roof penetrations while ensuring system stability.

To maximize energy generation, panels should be installed at an optimal tilt angle, usually between 20-40 degrees, depending on latitude. Adequate spacing between panel rows prevents self-shading and allows for maintenance access. The design must also account for existing rooftop equipment, such as HVAC units and skylights, while maintaining clear paths for emergency access.

Professional engineers evaluate factors like wind uplift resistance, seismic requirements, and drainage patterns to ensure the array’s long-term performance and roof integrity.

Energy Storage Solutions

Effective energy storage is crucial for maximizing the benefits of a solar-powered warehouse system. Modern lithium-ion battery installations, coupled with advanced energy storage management systems, ensure consistent power supply during non-peak production hours and cloudy days. These systems typically include battery banks sized according to the facility’s energy requirements, power conditioning equipment, and smart controllers that optimize charging and discharging cycles.

Most warehouse installations utilize modular battery systems that can be scaled as energy needs grow. The standard configuration includes primary storage units ranging from 50kWh to 1MWh, depending on facility size and operational demands. These systems integrate seamlessly with existing electrical infrastructure and can provide emergency backup power during grid outages.

Modern storage solutions also feature predictive analytics capabilities that anticipate energy consumption patterns and adjust storage strategies accordingly. This intelligent approach to power management helps warehouses maintain optimal energy reserves while reducing operational costs and maximizing the return on solar investment.

Smart Energy Management Systems

Modern smart energy management systems are essential components of solar-powered warehouses, offering real-time monitoring and precise control over energy consumption. These sophisticated systems integrate advanced sensors, data analytics, and automated controls to optimize power usage and distribution throughout the facility.

The core functionality includes load balancing between solar generation and grid power, automated switching during peak demand periods, and intelligent storage management for battery systems. Through user-friendly dashboards, facility managers can monitor key performance indicators such as energy production, consumption patterns, and system efficiency in real-time.

Advanced features typically include predictive analytics that forecast energy needs based on historical data and weather patterns, enabling proactive adjustments to maximize solar utilization. These systems also facilitate demand response programs, automatically reducing non-essential power usage during high-demand periods to optimize cost savings.

Integration with building management systems allows for automated control of lighting, HVAC, and other power-intensive systems, ensuring they operate at peak efficiency while prioritizing solar power usage. The resulting data helps identify opportunities for further optimization and supports strategic decision-making for future energy investments.

Implementation and Integration Strategies

Project Planning and Timeline

The successful implementation of a solar-powered warehouse system requires careful planning and a well-structured timeline. A typical transition to solar energy follows a six-phase implementation process spanning approximately 6-12 months.

Phase 1 (Weeks 1-4): Initial assessment and feasibility study, including energy consumption analysis, roof structural evaluation, and preliminary system design.

Phase 2 (Weeks 5-8): Detailed project planning, encompassing system specifications, contractor selection, and permit application preparation.

Phase 3 (Weeks 9-12): Securing necessary permits and approvals from local authorities, utility companies, and relevant regulatory bodies.

Phase 4 (Weeks 13-16): Equipment procurement and logistics planning, including solar panels, inverters, and mounting systems.

Phase 5 (Weeks 17-20): System installation and infrastructure development, covering panel mounting, electrical work, and monitoring system setup.

Phase 6 (Weeks 21-24): Testing, commissioning, and system optimization, followed by staff training and handover procedures.

Regular milestone reviews should be conducted throughout the implementation process to ensure adherence to timelines and budget constraints. Contingency plans should account for potential delays due to weather conditions, equipment delivery, or regulatory approval processes. This systematic approach ensures a smooth transition while minimizing disruption to warehouse operations.

Minimizing Operational Disruption

Implementing solar power in an operational warehouse requires careful planning to minimize disruption to daily activities. A phased installation approach allows warehouses to maintain regular operations while transitioning to solar energy. The process typically begins with preliminary work during off-peak hours, such as electrical system upgrades and roof reinforcement assessments.

Installation teams commonly work in designated sections, completing one area before moving to the next. This methodical approach ensures that only specific zones are temporarily affected, allowing operations to continue in other parts of the facility. Advanced planning with warehouse managers helps identify optimal installation windows that align with slower business periods.

Many successful installations utilize weekend and evening hours for major equipment placement. The mounting of solar panels and inverters can be scheduled during these times to minimize impact on loading dock operations and material handling activities. Mobile scaffolding and temporary barriers help maintain safety while allowing warehouse traffic to flow around work zones.

Communication plays a crucial role in smooth implementation. Establishing clear protocols between installation teams and warehouse staff ensures everyone understands restricted areas and alternative routes. Some facilities create temporary workflow modifications, such as redistributing storage areas or adjusting picking routes, to accommodate installation activities.

Project managers should develop contingency plans for weather delays and unexpected challenges, incorporating buffer time into the installation schedule to prevent disruption to critical warehouse operations. This strategic approach has enabled many facilities to complete solar installations while maintaining productivity levels above 90%.

Real-World Success Stories

Large Distribution Center Case Study

In 2021, XYZ Logistics transformed their 500,000-square-foot distribution center in Phoenix, Arizona, into a model of sustainable operations through a comprehensive solar installation project. The facility now features a 2.5-megawatt rooftop solar array consisting of 6,250 high-efficiency panels, making it one of the largest warehouse solar installations in the Southwest.

The project required an initial investment of $4.2 million, offset by federal tax incentives and local utility rebates totaling $1.3 million. The system generates approximately 4.1 million kWh of electricity annually, covering 85% of the facility’s total energy consumption. This has resulted in annual utility savings of $425,000, putting the project on track for a 7-year ROI.

The installation included structural reinforcement of the roof, smart inverter technology, and an advanced energy management system that optimizes power distribution during peak demand periods. The facility also incorporated energy storage solutions with a 500kWh battery system, enabling operations to continue during grid outages.

Beyond financial benefits, the project reduced the facility’s carbon footprint by 2,900 metric tons of CO2 annually. The success of this implementation has led XYZ Logistics to announce similar installations across their national network of distribution centers, demonstrating the scalability and reliability of warehouse solar solutions.

Small to Medium Warehouse Applications

Small to medium warehouses can effectively implement solar power solutions through carefully tailored systems that match their specific energy requirements and available roof space. A typical 50,000-square-foot warehouse can accommodate a 250-400 kW solar installation, potentially offsetting 70-90% of its energy consumption.

These facilities often benefit from rooftop-mounted systems, which utilize existing structural elements without requiring additional land. Modern solar panels, combined with smart inverter technology, can be configured to maximize energy production even with limited roof space. For example, a 20,000-square-foot facility in Arizona implemented a 150 kW system that reduced its annual energy costs by 65%.

Storage facilities and distribution centers ranging from 10,000 to 75,000 square feet have successfully adopted hybrid approaches, combining solar panels with energy-efficient lighting and HVAC systems. This integrated strategy typically delivers a return on investment within 4-6 years.

Key considerations for smaller facilities include:

– Modular system design allowing for future expansion

– Strategic panel placement to avoid HVAC units and skylights

– Integration with existing building management systems

– Battery storage options for enhanced energy independence

Many small to medium warehouses have found success with power purchase agreements (PPAs), which eliminate upfront costs while providing immediate energy savings. This financing model has enabled facilities with limited capital to transition to solar power while maintaining operational efficiency.

The implementation of solar power in warehouse facilities represents a transformative opportunity for businesses to achieve both environmental sustainability and operational efficiency. By harnessing solar energy, warehouse operators can significantly reduce their carbon footprint while securing long-term energy cost savings that directly impact their bottom line. The compelling combination of decreased utility expenses, available tax incentives, and enhanced corporate social responsibility makes solar power an increasingly attractive investment for forward-thinking businesses.

As energy costs continue to rise and environmental regulations become more stringent, warehouses that embrace solar power position themselves advantageously for the future. The proven track record of successful solar installations across various warehouse facilities demonstrates both the technical feasibility and financial viability of this renewable energy solution.

For warehouse operators considering solar power implementation, the time to act is now. Begin by conducting a comprehensive site assessment, consulting with qualified solar providers, and exploring available financing options. With proper planning and execution, a solar-powered warehouse can deliver substantial returns while contributing to a more sustainable future for generations to come.