Circular energy systems are revolutionizing how businesses approach sustainability and operational efficiency. By integrating renewable energy sources, waste-to-energy conversion, and smart grid technologies, organizations can create self-sustaining energy ecosystems that dramatically reduce costs while advancing environmental goals. This innovative approach transforms traditional linear energy consumption into a closed-loop system where waste becomes a valuable resource, and energy flows are optimized through advanced monitoring and management systems.

The concept extends beyond simple renewable energy adoption, encompassing comprehensive resource recovery, energy storage solutions, and intelligent distribution networks. Leading corporations worldwide are already demonstrating the viability of circular energy systems, achieving up to 40% reduction in energy costs while significantly decreasing their carbon footprint. These systems represent a paradigm shift in energy management, offering a practical pathway to both environmental sustainability and economic advantage.

For facility managers and business leaders, circular energy presents an opportunity to future-proof operations while meeting increasingly stringent environmental regulations. The integration of these systems not only ensures energy security but also positions organizations at the forefront of the sustainable business revolution, creating lasting value for stakeholders and the planet alike.

The Circular Energy Revolution in Commercial Settings

Components of a Circular Energy Ecosystem

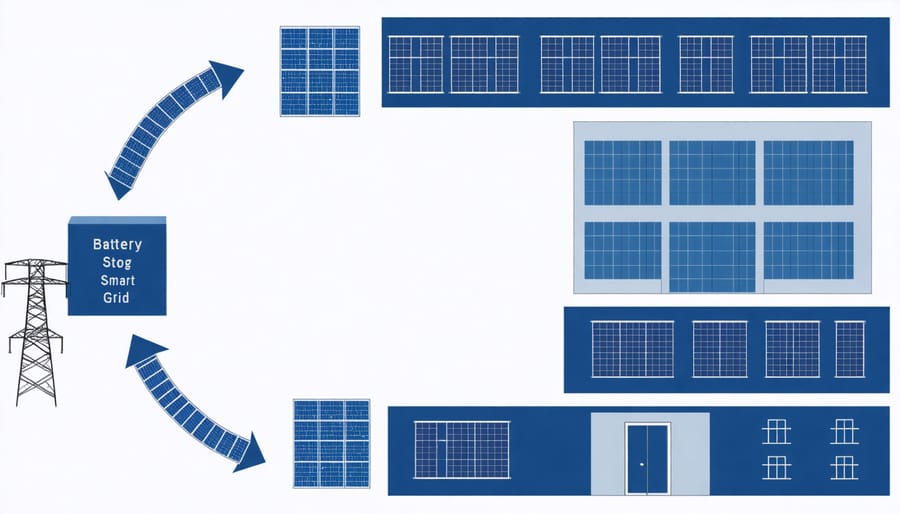

A circular energy ecosystem comprises several interconnected components that work together to maximize efficiency and minimize waste. At its core, solar PV systems serve as the primary renewable energy generators, converting sunlight into electricity while producing minimal environmental impact. These systems are designed to operate at peak efficiency during daylight hours and can be scaled to meet varying energy demands.

Energy storage solutions form the second critical component, typically utilizing advanced battery systems or thermal storage technologies. These storage systems address the intermittent nature of solar power by storing excess energy during peak production periods and releasing it when needed, ensuring consistent power availability regardless of weather conditions or time of day.

Smart grid integration represents the intelligent backbone of the circular energy ecosystem, connecting and optimizing all components through sophisticated monitoring and control systems. This integration enables real-time load balancing, demand response management, and automated energy distribution, significantly improving overall system efficiency.

The ecosystem also incorporates energy management systems (EMS) that utilize artificial intelligence and machine learning algorithms to predict energy demands, optimize consumption patterns, and identify potential efficiency improvements. These systems continuously analyze data from multiple sources to make informed decisions about energy distribution and storage.

Finally, waste heat recovery systems capture and repurpose thermal energy from various processes, directing it toward useful applications such as heating, cooling, or industrial processes. This component ensures that otherwise wasted energy is recirculated within the system, maximizing resource utilization and reducing operational costs.

Resource Integration Strategies

Effective resource integration in circular energy systems requires a strategic approach that combines multiple energy sources and optimization techniques. The key lies in creating seamless connections between various energy streams while minimizing waste and maximizing efficiency. Organizations can implement smart grid technologies that enable real-time monitoring and adjustment of energy flows, ensuring optimal resource utilization across different operational areas.

A crucial component of successful integration is the implementation of advanced energy storage systems that can balance supply and demand fluctuations. These systems work in conjunction with renewable energy sources, capturing excess energy during peak production periods and releasing it when needed. This integration helps maintain system stability and reduces reliance on grid power during high-demand periods.

Organizations should also consider implementing heat recovery systems that capture and repurpose waste heat from industrial processes. This recovered energy can be used for space heating, water heating, or even converted back into electricity through appropriate technologies. The integration of waste-to-energy systems further enhances resource utilization by converting organic waste into biogas or other forms of useful energy.

Digital twin technology and artificial intelligence play vital roles in optimizing resource integration. These tools analyze operational data in real-time, predicting energy demands and automatically adjusting system parameters to maintain peak efficiency. By incorporating smart meters and IoT sensors, facilities can create a comprehensive energy management ecosystem that continuously monitors and optimizes resource allocation.

Success in resource integration often depends on establishing clear communication protocols between different system components and implementing robust control mechanisms that can respond quickly to changing conditions. This approach ensures maximum energy efficiency while maintaining operational reliability.

Real-World Applications and Benefits

Commercial Success Stories

Several prominent companies have successfully implemented circular energy systems, demonstrating both environmental and economic benefits. IKEA’s distribution center in Staten Island, New York, achieved energy independence through an integrated system combining solar panels, wind turbines, and energy storage solutions, reducing operational costs by 40% within three years of implementation.

Google’s data center in Hamina, Finland, exemplifies circular energy principles by using seawater cooling systems and converting waste heat into district heating for local communities. This innovative approach has decreased their energy consumption by 50% compared to conventional data centers while providing heating for 20,000 households.

Unilever’s factory in Dubai implemented a closed-loop energy system that converts food waste into biogas, powering 75% of the facility’s operations. This initiative reduced their energy costs by €2.1 million annually while eliminating 10,000 tons of waste from landfills.

The Mars Corporation’s manufacturing facility in Mogi Mirim, Brazil, operates on a comprehensive circular energy model incorporating solar, biomass, and waste-to-energy systems. Their integrated approach has achieved 100% renewable energy usage and generates a 15% energy surplus that’s fed back into the local grid.

These success stories demonstrate that circular energy systems not only support environmental goals but also deliver substantial cost savings and operational efficiency improvements, making them increasingly attractive to forward-thinking businesses.

ROI and Cost Analysis

Implementing circular energy systems presents compelling financial advantages for organizations. A comprehensive return on investment analysis typically shows payback periods ranging from 3 to 7 years, depending on the scale and complexity of implementation.

Initial capital costs vary significantly based on system size and integration requirements. Small-scale implementations generally range from $50,000 to $250,000, while larger industrial systems may require investments of $1-5 million. However, these investments are offset by multiple revenue streams and cost reductions:

• Energy cost savings: 20-40% reduction in utility expenses

• Waste management savings: 15-30% decrease in disposal costs

• Resource recovery value: Additional revenue from recovered materials

• Carbon credit opportunities: Potential earnings from emissions reduction

• Operational efficiency gains: 10-25% improvement in resource utilization

Organizations implementing circular energy systems report average annual returns of 12-18% on their initial investment. Cost-benefit analyses show that facilities over 50,000 square feet achieve the most favorable economics due to economies of scale.

Key financial benefits include reduced exposure to energy price volatility, lower operational costs, and increased asset value. Government incentives, tax benefits, and green financing options can further improve the financial proposition, potentially reducing payback periods by 1-2 years.

Implementation Framework

Assessment and Planning

Successful implementation of circular energy systems begins with a comprehensive facility assessment and strategic planning process. Start by conducting an energy audit to identify current consumption patterns, peak usage periods, and potential waste streams that could be integrated into the energy cycle. This baseline data serves as the foundation for developing targeted solutions.

Create a detailed implementation roadmap that includes both short-term and long-term objectives. Consider factors such as existing infrastructure compatibility, space requirements, and regulatory compliance. Prioritize projects based on ROI potential, implementation complexity, and available resources.

Evaluate potential technologies and systems that align with your facility’s specific needs. This may include combined heat and power systems, waste-to-energy solutions, or renewable energy integration. Consider scalability options to accommodate future growth and changing energy demands.

Develop key performance indicators (KPIs) to measure success, such as energy recovery rates, cost savings, and carbon footprint reduction. Establish a monitoring and verification system to track progress and identify optimization opportunities. Remember to account for maintenance requirements and staff training needs in your planning phase to ensure long-term success.

Integration and Optimization

Successful integration of circular energy systems requires careful planning and continuous monitoring for optimal performance. Start by conducting a comprehensive energy audit to identify potential synergies between different energy streams and waste sources. Implement smart monitoring systems with real-time data collection to track energy flows and system efficiency.

Key optimization strategies include load balancing across different energy sources, implementing predictive maintenance protocols, and utilizing advanced control systems to maximize energy recovery. Consider implementing machine learning algorithms to automatically adjust system parameters based on usage patterns and environmental conditions.

Regular system calibration and performance reviews are essential. Establish clear KPIs for energy recovery rates, cost savings, and carbon reduction. Update operational procedures based on collected data and emerging technologies. Train facility personnel in system operation and maintenance to ensure consistent performance.

Partner with experienced system integrators who understand both traditional and renewable energy systems. Create a detailed implementation timeline that minimizes disruption to existing operations. Consider phased implementation to allow for testing and optimization of individual components before full system integration.

Remember that optimization is an ongoing process. Regular stakeholder meetings and performance reviews help identify new opportunities for improvement and ensure the system continues to meet evolving business needs.

Circular energy represents a transformative approach to resource management that businesses can no longer afford to ignore. By integrating renewable energy sources, maximizing efficiency through smart technologies, and implementing waste-to-energy solutions, organizations can create self-sustaining energy ecosystems that benefit both their bottom line and the environment. The successful case studies presented demonstrate that circular energy systems are not just theoretical concepts but practical, profitable solutions already driving business success across various industries.

To begin your circular energy journey, start by conducting an energy audit, identifying potential waste streams, and assessing renewable energy opportunities specific to your facility. Consider partnering with experienced energy consultants who can help develop a tailored implementation strategy. Remember that transitioning to circular energy systems can be approached in phases, allowing for manageable investment and measurable results at each stage. Take the first step today by exploring available government incentives and connecting with industry partners who can support your organization’s transition to a more sustainable, circular energy future.