Solar panel Z brackets serve as the critical foundation for secure and efficient rooftop solar installations, providing the essential connection between mounting rails and roof surfaces. These versatile mounting components deliver superior load distribution while maintaining water-tight roof integrity through their distinctive Z-shaped design. Professional installers rely on Z brackets to achieve optimal panel angles, maximize energy production, and ensure installations meet strict building codes and wind load requirements. For commercial and industrial applications, these brackets offer the dual advantage of rapid installation and long-term structural reliability, making them a cornerstone component in modern solar mounting systems. Understanding proper Z bracket selection, spacing, and installation protocols directly impacts system performance, maintenance requirements, and the overall return on solar investments.

What Makes Z Brackets Essential for Commercial Solar Installations

Design Features and Load Capacity

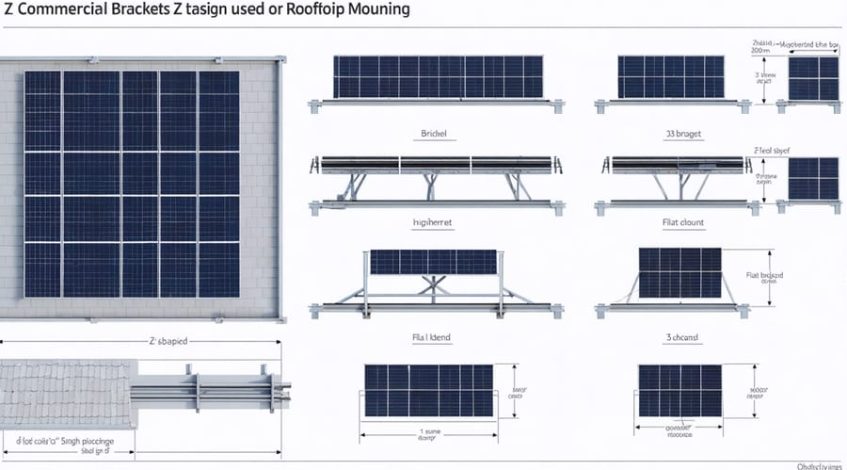

Z brackets are engineered with precision-grade aluminum or stainless steel to provide optimal support for solar panel installations. These robust mounting solutions typically feature a load capacity ranging from 2.4 kN to 4.8 kN per bracket, depending on the specific model and manufacturer specifications.

The distinctive Z-shaped design creates three mounting points that efficiently distribute weight across the roof structure while maintaining a low profile. This configuration allows for a 2-3 inch elevation between the roof surface and solar panels, facilitating proper airflow and reducing heat buildup beneath the array.

Most commercial-grade Z brackets incorporate pre-drilled holes for easy installation and feature anti-corrosion coatings that ensure longevity in various weather conditions. The standard dimensions accommodate panels ranging from 60-cell to 72-cell configurations, with adjustable tilt angles between 10-45 degrees for optimal sun exposure.

The structural integrity of Z brackets is enhanced by reinforced bend points and load-bearing surfaces that minimize the risk of material fatigue. When properly installed, these brackets can withstand wind speeds up to 140 mph and snow loads of 50 pounds per square foot, making them suitable for diverse climate zones.

Material Composition and Durability

Solar panel Z brackets are typically manufactured from high-grade aluminum or stainless steel, ensuring optimal strength and longevity in outdoor environments. The most common material choice is 6061-T6 aluminum alloy, which offers an excellent balance of corrosion resistance and structural integrity. These brackets undergo specialized treatments, including anodizing or galvanization, to enhance their weather-resistant properties.

The materials used can withstand extreme temperature variations, from -40°F to 185°F, making them suitable for diverse climate conditions. Most quality Z brackets feature a minimum thickness of 3mm and incorporate pre-drilled mounting holes with weather-sealed edges to prevent water infiltration. Their corrosion-resistant properties ensure a service life that typically matches or exceeds the 25-year warranty period of most solar panels, providing long-term reliability for rooftop solar installations.

Professional Installation Best Practices

Spacing and Alignment Considerations

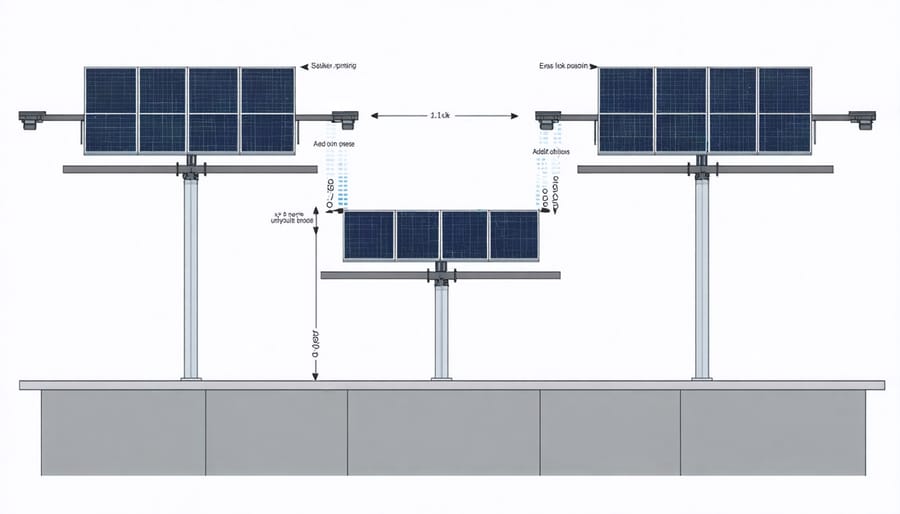

Proper spacing and alignment of Z brackets are crucial for optimal solar panel performance and structural integrity. The standard spacing between Z brackets typically ranges from 48 to 72 inches, depending on local wind load requirements and panel specifications. When installing multiple rows, maintain a minimum gap of 1 inch between panels to allow for thermal expansion and facilitate maintenance access.

For maximum effectiveness, panel positioning and alignment must account for both vertical and horizontal forces. Z brackets should be positioned at least 12 inches from the panel edges to ensure proper load distribution. The mounting surface must be level within 1/4 inch per foot to prevent uneven stress on the brackets and panels.

Critical measurements include:

– Edge-to-bracket distance: 12-16 inches

– Inter-row spacing: 24-36 inches (depending on roof pitch)

– Minimum clearance from roof surface: 3-4 inches

– Bracket-to-bracket horizontal alignment tolerance: ±1/8 inch

Always consult local building codes and manufacturer specifications for site-specific requirements, as environmental factors may necessitate adjustments to these standard measurements.

Torque Specifications and Safety Guidelines

When installing solar panel Z brackets, proper torque specifications and safety protocols are essential for optimal solar panel performance and long-term structural integrity. The recommended torque for mounting bolts typically ranges from 20-25 ft-lbs (27-34 Nm), though specific values may vary by manufacturer and local building codes.

Always use stainless steel hardware rated for outdoor use, including lag bolts (minimum 5/16″ diameter), washers, and lock washers. Before installation, verify the roof structure can support the additional load, and ensure proper waterproofing at all penetration points.

Safety guidelines mandate the use of appropriate personal protective equipment (PPE), including non-slip footwear, safety harnesses, and cut-resistant gloves. Installation teams must follow OSHA fall protection standards when working at heights. Regular inspection of mounting hardware is recommended, with particular attention to signs of corrosion or loosening. Document all torque measurements during installation for future reference and compliance purposes.

Choosing the Right Z Brackets for Your Project

Load Calculations and System Requirements

To determine appropriate Z bracket specifications, calculate the total load requirements by combining the solar panel weight, snow load factors, and wind uplift forces specific to your installation location. Standard Z brackets typically support 30-50 pounds per mount point, but always verify manufacturer specifications. Factor in the panel’s dimensions and mounting angle to ensure proper load distribution and to avoid common installation mistakes. For commercial installations, consider using a safety factor of 1.5 times the calculated load. The mounting surface’s structural integrity must also be evaluated, with particular attention to roof composition and underlying support structures. Professional engineering consultation is recommended for installations exceeding 10kW or in areas with extreme weather conditions.

Compatibility with Different Roof Types

Z brackets demonstrate exceptional versatility across various commercial roofing systems. For metal roofs, these brackets provide secure attachment points while maintaining weatherproofing integrity through EPDM gaskets and appropriate flashing. On concrete tile roofs, extended Z brackets accommodate the height variation between tiles, ensuring proper elevation and weight distribution.

When installing on asphalt shingle roofs, specially designed Z brackets with integrated flashing systems prevent water infiltration while maintaining the roof’s warranty. For standing seam metal roofs, non-penetrating clamp-style Z brackets preserve the roof’s integrity without compromising its weatherproof characteristics.

Flat commercial roofs require low-profile Z brackets with enhanced waterproofing features and appropriate ballasting systems. Each installation must account for the specific roofing material’s load capacity, thermal expansion properties, and warranty requirements. Professional assessment is essential to select the appropriate Z bracket configuration for your specific roofing system.

Selecting and installing the right Z brackets is crucial for the long-term success of commercial solar installations. These components serve as the foundation of your solar mounting system, directly impacting system durability, safety, and overall performance. Proper bracket selection ensures optimal panel orientation, load distribution, and structural integrity while minimizing the risk of weather-related damage. By carefully considering factors such as roof type, local weather conditions, and specific mounting requirements, facility managers can maximize their solar investment’s ROI. Remember that expert installation following manufacturer specifications is equally important as the selection process. When done correctly, Z bracket implementation creates a reliable foundation for solar arrays that can provide clean, renewable energy for decades to come.