Solar panels represent a critical long-term investment that spans 25-30 years of clean energy production, making lifecycle management essential for maximizing returns and protecting your solar investment. From initial manufacturing to end-of-life recycling, each phase demands strategic oversight to optimize performance and maintain efficiency. Modern solar installations deliver peak efficiency of 15-20% during their first decade, gradually declining at a predictable rate of 0.5-1% annually thereafter. This degradation pattern, combined with proper maintenance protocols, enables facility managers to accurately forecast energy production and plan for replacement cycles. Understanding these lifecycle stages – procurement, installation, operation, maintenance, and decommissioning – provides decision-makers with the framework needed to maximize their renewable energy assets while meeting sustainability goals and regulatory requirements. As global solar adoption accelerates, mastering the complete lifecycle management process becomes increasingly crucial for maintaining competitive advantage in today’s energy-conscious business environment.

The Four Phases of Solar Panel Lifecycle

Manufacturing and Quality Control

The manufacturing of solar panels involves a sophisticated multi-stage process that begins with the purification of silicon to achieve semiconductor-grade material. This refined silicon is then formed into ingots and sliced into thin wafers, which serve as the foundation for photovoltaic cells. Manufacturers apply anti-reflective coatings and metal contacts to optimize energy absorption and electrical conductivity.

Quality control measures are implemented at each production stage, with rigorous testing protocols ensuring panels meet international standards such as IEC 61215 and IEC 61730. These standards evaluate mechanical durability, electrical performance, and safety parameters. Manufacturers typically conduct flash testing to measure power output and efficiency ratings under standard test conditions (STC).

Material selection plays a crucial role in panel longevity and performance. High-grade silicon, EVA (ethylene vinyl acetate) encapsulation, and tempered glass are carefully chosen to withstand environmental stresses while maintaining optimal energy conversion rates. Leading manufacturers employ automated inspection systems and electron microscopy to detect micro-cracks and manufacturing defects.

Production facilities maintain strict environmental controls, including cleanroom environments for cell manufacturing, to prevent contamination that could impact panel efficiency. Each batch undergoes performance testing, including hot-spot testing, mechanical load testing, and thermal cycling to simulate real-world conditions.

Modern manufacturing facilities increasingly implement Industry 4.0 practices, utilizing artificial intelligence and machine learning for quality assurance. This advanced approach helps maintain consistent production standards while reducing waste and optimizing resource utilization. Manufacturers typically offer 25-year performance warranties, reflecting confidence in their quality control processes and material selection.

Installation and Commissioning

The installation and commissioning phase of solar panels represents a critical milestone that significantly influences their long-term performance and reliability. Professional installers begin by conducting a detailed site assessment, evaluating factors such as roof structural integrity, optimal panel orientation, and shading analysis to maximize energy generation potential.

During installation, mounting systems are securely attached to the building structure, following local building codes and manufacturer specifications. Proper racking installation ensures panels can withstand environmental stresses while maintaining optimal tilt angles for maximum sun exposure. Experienced teams carefully handle panels during mounting to prevent micro-cracks or damage that could impact future performance.

The electrical integration phase involves connecting panels in series or parallel configurations, installing inverters, and implementing monitoring systems. Proper wire management and weatherproof connections are essential to prevent system degradation and ensure safety compliance. Quality control measures include thorough testing of all electrical connections and verification of grounding systems.

Commissioning involves a comprehensive system verification process. Technicians perform detailed performance tests, including string voltage measurements, insulation resistance testing, and overall system efficiency verification. Modern monitoring systems are calibrated to establish performance baselines and enable future tracking of system health.

For commercial installations, the commissioning process typically includes staff training on basic system operation and maintenance procedures. Documentation of as-built drawings, equipment warranties, and operational parameters is provided to facility managers for future reference.

A well-executed installation and commissioning process not only ensures immediate system performance but also sets the foundation for optimal long-term operation and maintenance efficiency.

Operation and Maintenance

Regular operation and maintenance are crucial for maximizing the performance and longevity of commercial solar installations. A well-structured maintenance program, including preventive maintenance protocols, can significantly extend system life while ensuring optimal energy generation.

Key maintenance activities include regular panel cleaning to remove dust, debris, and bird droppings that can reduce efficiency by up to 25%. This should be performed quarterly in most environments, though facilities in dusty or high-pollution areas may require more frequent cleaning. Professional inspection of electrical connections, mounting hardware, and inverter performance should be conducted bi-annually.

Monitoring systems play a vital role in daily operations, providing real-time performance data and early warning of potential issues. Modern monitoring platforms can track individual panel output, system efficiency, and environmental conditions, enabling proactive maintenance scheduling and swift response to performance degradation.

Professional maintenance teams should conduct thorough annual assessments, including thermal imaging to identify hot spots, degraded cells, or connection issues. They should also verify proper system grounding, inspect for water damage or corrosion, and ensure all safety systems are functioning correctly.

Maintenance costs typically range from 0.5% to 1% of the initial system cost annually, making it a modest investment compared to the potential revenue loss from system underperformance. Organizations should maintain detailed maintenance logs and performance records, which are valuable for warranty claims and system optimization.

Emergency response protocols should be established, with clear procedures for addressing system failures, weather damage, or safety incidents. Having qualified personnel and replacement components readily available minimizes system downtime and associated revenue loss.

For optimal results, facility managers should partner with certified solar maintenance providers who understand local environmental conditions and regulatory requirements. This ensures compliance with safety standards while maximizing system performance throughout its operational lifetime.

End-of-Life Management and Recycling

As solar installations reach the end of their operational life, implementing sustainable disposal practices becomes crucial for environmental stewardship and regulatory compliance. Modern solar panels typically have a lifespan of 25-30 years, after which they require proper decommissioning and recycling to recover valuable materials and minimize environmental impact.

The recycling process involves separating various components, including aluminum frames, glass panels, silicon cells, and precious metals. Specialized recycling facilities can recover up to 95% of these materials, which can then be repurposed for new solar panels or other industrial applications. This circular economy approach not only reduces waste but also decreases the carbon footprint associated with new panel production.

Several manufacturers now offer take-back programs, simplifying the end-of-life management process for business owners. These programs often include professional removal, transportation, and processing services, ensuring compliance with local and international regulations. Organizations should plan for panel disposal during the initial installation phase, factoring in recycling costs and potential material recovery value.

As regulations evolve and recycling technologies advance, the end-of-life management of solar panels is becoming more efficient and cost-effective. Forward-thinking businesses are increasingly incorporating panel recycling into their sustainability strategies, recognizing both the environmental benefits and potential future value of recovered materials. Industry experts recommend maintaining detailed records of panel specifications and working with certified recycling partners to ensure proper handling and maximum material recovery.

Optimizing System Performance Through Lifecycle Management

Performance Monitoring Systems

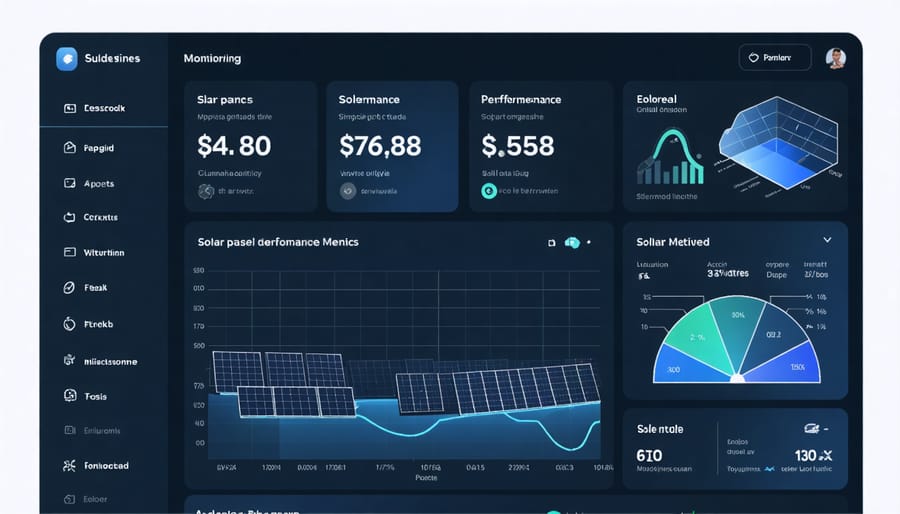

Modern performance monitoring systems are essential tools for maximizing solar panel efficiency throughout their operational life. These sophisticated platforms utilize advanced sensors, data analytics, and real-time monitoring capabilities to track key performance indicators such as energy output, conversion efficiency, and system health.

Industry-standard monitoring solutions typically include remote access dashboards, automated alert systems, and predictive maintenance features. These tools enable facility managers to detect potential issues before they escalate, optimize panel orientation based on performance data, and ensure consistent energy generation levels.

Key monitoring parameters include DC/AC power output, voltage levels, weather conditions, and panel temperature. Advanced systems also incorporate machine learning algorithms to establish performance benchmarks and identify deviations that may indicate maintenance needs. This data-driven approach helps organizations maintain optimal system efficiency while extending the operational lifespan of their solar installations.

Regular performance monitoring also supports warranty compliance documentation and helps facility managers make informed decisions about maintenance scheduling and component replacement timing.

Preventive Maintenance Schedules

A well-structured preventive maintenance schedule is crucial for maximizing solar panel performance and longevity. Quarterly visual inspections should be conducted to check for physical damage, debris accumulation, and potential shading issues. These inspections can be performed by facility staff using a basic checklist.

Professional cleaning should be scheduled bi-annually, with additional cleanings as needed in areas with high dust, pollen, or industrial pollution. The cleaning process should utilize specialized equipment and deionized water to prevent mineral deposits and surface damage.

Annual comprehensive maintenance should include:

– Electrical systems inspection and testing

– Mounting hardware tightness verification

– Inverter performance evaluation

– Wiring and connection point examination

– Performance data analysis

Every three years, thermal imaging inspections are recommended to identify potential hot spots or failing components. Additionally, inverter maintenance or replacement may be necessary every 10-15 years, depending on the model and operating conditions.

Documentation of all maintenance activities is essential for warranty compliance and performance tracking. Many modern monitoring systems can help facility managers optimize these maintenance schedules based on real-time performance data.

Understanding the lifecycle of solar panels is crucial for making informed decisions about solar energy investments. From manufacturing to end-of-life management, each stage presents opportunities for optimization and responsible stewardship. By implementing proper maintenance protocols and working with certified installers and recycling partners, organizations can maximize their solar panels’ lifespan beyond the standard 25-30 years while maintaining optimal performance. Regular monitoring, timely repairs, and planning for eventual recycling or repurposing are essential practices for sustainable solar asset management. We recommend conducting thorough due diligence when selecting manufacturers, establishing comprehensive maintenance schedules, and developing end-of-life strategies well in advance. These proactive measures will ensure maximum return on investment while contributing to environmental sustainability goals and supporting the circular economy in the renewable energy sector.