Solid-state batteries represent a revolutionary leap in energy storage technology, combining advanced ceramic or polymer electrolytes with lithium metal anodes to deliver unprecedented performance and safety. Unlike traditional lithium-ion batteries with liquid electrolytes, these next-generation power cells utilize solid components throughout their construction, eliminating the risk of leakage and thermal runaway. Their core architecture typically consists of a solid electrolyte layer sandwiched between a lithium metal anode and a cathode composed of lithium-containing compounds such as lithium cobalt oxide or lithium iron phosphate.

The materials chosen for solid-state batteries directly influence their performance characteristics, with leading manufacturers exploring various combinations of sulfide-based ceramics, oxide-based ceramics, and polymer-based compounds. These sophisticated material choices enable higher energy densities, faster charging capabilities, and extended operational lifespans compared to conventional battery technologies, making them particularly attractive for electric vehicle applications and grid-scale energy storage solutions.

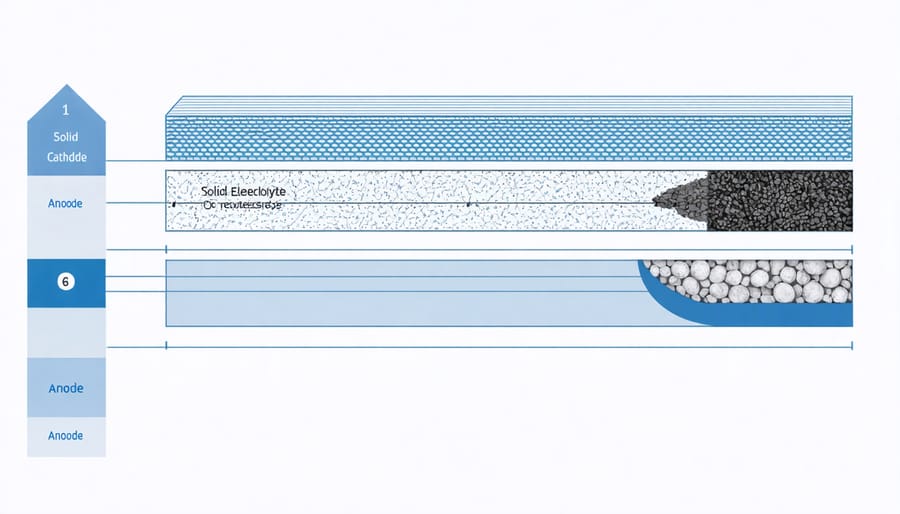

Core Components of Solid-State Batteries

Solid Electrolytes

Solid electrolytes are the defining feature that sets solid-state batteries apart from traditional battery materials. These materials conduct ions between the cathode and anode while serving as a physical barrier, eliminating the need for liquid electrolytes and their associated safety risks.

The most promising solid electrolyte materials fall into three main categories: oxide-based ceramics, sulfide-based materials, and polymer electrolytes. Oxide ceramics, such as LLZO (Li7La3Zr2O12), offer exceptional chemical stability and safety but face challenges with conductivity at room temperature. Sulfide-based electrolytes, including Li10GeP2S12 (LGPS), provide superior ionic conductivity but are more sensitive to air and moisture.

Polymer electrolytes, particularly those based on PEO (polyethylene oxide), present a balance between performance and manufacturability. These materials can be processed at lower temperatures and offer better flexibility than ceramic alternatives, making them attractive for large-scale production.

Recent developments have focused on composite electrolytes that combine the advantages of different material classes. For example, ceramic-polymer hybrids can achieve both high conductivity and mechanical stability while remaining easier to manufacture than pure ceramic systems. These innovations are crucial for advancing solid-state battery technology toward commercial viability.

Cathode and Anode Materials

The electrode materials in solid-state batteries play a crucial role in determining overall performance, energy density, and longevity. For cathode materials, manufacturers typically employ lithium-containing compounds such as lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), and nickel-manganese-cobalt (NMC) compositions. These materials provide stable platforms for lithium-ion storage and transfer while maintaining structural integrity during charging cycles.

On the anode side, solid-state batteries often utilize lithium metal, which offers significantly higher energy density compared to traditional graphite anodes found in liquid electrolyte batteries. Some designs also incorporate silicon-based materials or carbon composites to enhance stability and cycling performance. The selection of anode materials directly impacts the battery’s charging speed and energy storage capacity.

The interface between electrodes and the solid electrolyte requires careful engineering to ensure optimal ion transfer and minimize resistance. Manufacturers often apply specialized coatings or interface layers to improve connectivity and reduce degradation over time. Recent developments have focused on nano-structured electrode materials that maximize the contact area with the electrolyte while maintaining mechanical stability.

The combination of advanced cathode and anode materials enables solid-state batteries to achieve higher energy densities, faster charging capabilities, and improved safety compared to conventional lithium-ion batteries. These characteristics make them particularly attractive for electric vehicle applications and grid-scale energy storage solutions.

Material Innovations

Ceramic-Based Materials

Ceramic-based materials form the cornerstone of modern solid-state battery technology, serving as both electrolytes and electrode components. These advanced ceramics, typically oxide-based or sulfide-based compounds, offer superior ionic conductivity while maintaining excellent thermal stability. Common materials include LLZO (Lithium Lanthanum Zirconium Oxide) and LAGP (Lithium Aluminum Germanium Phosphate), which have demonstrated remarkable performance in laboratory settings.

The primary advantage of ceramic materials lies in their ability to conduct lithium ions efficiently while preventing dendrite formation, a common failure mode in traditional liquid electrolyte batteries. These materials also exhibit exceptional chemical stability across a wide temperature range, contributing to enhanced battery safety and longevity.

Recent developments have focused on optimizing ceramic composition through dopants and specialized manufacturing processes to improve conductivity and reduce production costs. Industry leaders are particularly interested in ceramic-polymer composites, which combine the high conductivity of ceramics with the flexibility and processability of polymers, offering a promising path toward mass production of solid-state batteries.

Polymer-Based Solutions

Polymer-based solid-state batteries represent a significant advancement in battery technology, utilizing specialized polymer electrolytes to conduct ions between electrodes. These polymers, typically consisting of polyethylene oxide (PEO) or polyvinylidene fluoride (PVDF), offer unique advantages in battery design and performance.

The polymer electrolytes function at room temperature and provide excellent flexibility, making them ideal for various form factors and applications. Their key benefit lies in their ability to prevent dendrite formation, a common issue in traditional lithium-ion batteries that can lead to short circuits and safety hazards.

Major manufacturers are increasingly incorporating polymer-based solutions due to their cost-effectiveness and scalability in production. These materials enable faster charging capabilities while maintaining stable performance across different temperature ranges. The polymer matrix also serves as a natural separator, eliminating the need for additional components and simplifying the manufacturing process.

Recent developments have focused on enhancing polymer conductivity through the integration of ceramic particles, creating hybrid systems that combine the best properties of both materials. This approach has shown promising results in improving overall battery performance and longevity.

Manufacturing Processes

The manufacturing of solid-state batteries involves sophisticated battery production processes that differ significantly from traditional lithium-ion battery manufacturing. The process typically begins with the synthesis of solid electrolyte materials through methods such as solution processing, ball milling, or solid-state reactions. These materials are carefully processed to achieve specific particle sizes and compositions essential for optimal performance.

The assembly process starts with the preparation of the cathode layer, which involves mixing active materials with the solid electrolyte and conductive additives. This mixture is then compressed and sintered at high temperatures to create a dense, uniform layer. The solid electrolyte layer is prepared separately, often using techniques like tape casting or pressing, followed by high-temperature sintering to achieve the required density and ionic conductivity.

For the anode layer, lithium metal or other materials are carefully deposited onto a current collector. The critical step in manufacturing is the interface engineering between these layers, as good contact is essential for efficient ion transport. Manufacturers typically use specialized coating techniques and pressure-assisted sintering to ensure proper layer adhesion and reduce interfacial resistance.

Quality control is paramount throughout the manufacturing process, with continuous monitoring of layer thickness, density, and compositional uniformity. Advanced techniques such as atomic layer deposition and physical vapor deposition are often employed to create protective coatings and optimize interfaces between components.

The final assembly takes place in highly controlled environments to prevent contamination and moisture exposure, which can significantly impact battery performance. The completed cells undergo extensive testing and conditioning procedures before being integrated into battery modules or packs. While current manufacturing scales are limited, ongoing developments in automation and process optimization are steadily improving production efficiency and reducing costs.

Commercial Applications and Future Developments

Solid-state batteries are rapidly transitioning from laboratory concepts to commercial reality, with major automotive manufacturers leading the deployment. Toyota has announced plans to introduce its first solid-state battery vehicles by 2025, promising charging times under 10 minutes and extended range capabilities. Similarly, QuantumScape, backed by Volkswagen, is scaling up production facilities for commercial deployment by 2024.

In the consumer electronics sector, companies like Samsung and LG are developing solid-state batteries for smartphones and laptops, anticipating commercial release within the next few years. These implementations promise devices with longer battery life and enhanced safety features.

Looking ahead, the solid-state battery market is projected to reach $87.5 billion by 2030, driven by increasing demand for electric vehicles and renewable energy storage solutions. Research and development efforts are focusing on reducing production costs and scaling up manufacturing processes. Novel materials and fabrication techniques are being explored to improve energy density and cycle life further.

Grid-scale energy storage represents another promising application, with pilot projects already underway in several countries. These installations demonstrate the potential for solid-state batteries to provide more efficient and safer energy storage solutions for renewable power integration.

Emerging applications include aerospace, where solid-state batteries’ high energy density and safety characteristics make them ideal for electric aircraft and satellite systems. Medical devices and industrial automation sectors are also showing increased interest, particularly in applications requiring reliable, long-lasting power sources.

The technology’s continued evolution suggests a future where solid-state batteries could become the standard for energy storage across multiple industries, offering superior performance and safety compared to traditional lithium-ion batteries.

The careful selection of materials in solid-state battery development represents a critical factor in advancing energy storage technology. As we’ve explored, the combination of solid electrolytes, advanced cathodes, and innovative electrode materials creates batteries that are safer, more efficient, and longer-lasting than traditional lithium-ion alternatives. These material innovations are driving the transition toward more sustainable energy solutions across industries. With continued research and development in material science, solid-state batteries are positioned to revolutionize electric vehicles, renewable energy storage, and portable electronics. Their potential to deliver higher energy density, faster charging capabilities, and enhanced safety makes them an integral component of our sustainable energy future. As manufacturing processes evolve and costs decrease, solid-state batteries will play an increasingly important role in meeting global energy demands while supporting environmental goals.