In today’s dynamic energy landscape, demand response smart grid technology stands as a transformative force, enabling businesses to optimize their energy consumption while contributing to grid stability. By intelligently managing power usage during peak demand periods, organizations can reduce operational costs by 15-30% while earning valuable incentives from utilities. This sophisticated integration of real-time monitoring, automated controls, and predictive analytics creates a symbiotic relationship between energy consumers and providers, fundamentally reshaping how facilities interact with the power grid.

Advanced demand response systems now leverage artificial intelligence and IoT sensors to automatically adjust building systems—from HVAC to industrial processes—in response to grid signals, ensuring seamless operation while maximizing financial benefits. For facility managers and business leaders, this technology represents not just an energy management solution, but a strategic asset that enhances operational resilience, supports sustainability goals, and generates measurable ROI through reduced peak demand charges and participation in utility incentive programs.

As grid modernization accelerates and renewable energy integration expands, demand response capabilities have become essential for businesses seeking to optimize their energy investments and maintain competitive advantage in an increasingly energy-conscious marketplace.

The Business Case for Smart Grid Demand Response

Peak Demand Management Benefits

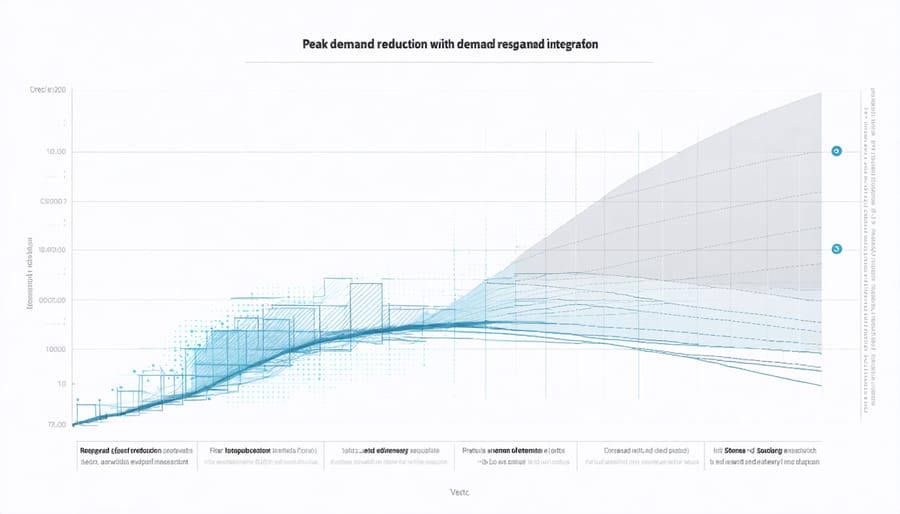

Peak demand management through demand response programs offers significant financial advantages for businesses by strategically reducing electricity consumption during high-cost periods. By implementing a solar energy management system alongside demand response capabilities, organizations can achieve substantial reductions in peak demand charges, which often constitute up to 30% of commercial electricity bills.

These programs enable businesses to automatically adjust their energy usage based on grid signals, shifting non-essential operations to off-peak hours. For example, a manufacturing facility might pre-cool spaces during early morning hours or reschedule energy-intensive processes to periods of lower demand. This strategic load management not only reduces operational costs but also helps stabilize the grid during critical periods.

The financial benefits extend beyond direct energy savings. Many utilities offer incentive payments for participation in demand response programs, creating an additional revenue stream. Organizations can typically expect a 10-20% reduction in their overall electricity costs through active participation in these programs, with some achieving even higher savings through sophisticated optimization strategies.

Utility Incentives and Programs

Utility companies offer various financial incentives to encourage participation in demand response programs, making it an attractive option for businesses and facility managers. Common incentives include bill credits, reduced electricity rates during off-peak hours, and performance-based payments calculated on the amount of load reduction achieved during demand response events.

Many utilities provide upfront rebates for installing smart grid-enabled equipment and automation systems that facilitate demand response participation. These rebates can cover up to 50% of equipment costs, significantly reducing the initial investment. Additionally, some programs offer annual enrollment bonuses and capacity payments for maintaining specific load reduction capabilities.

Performance incentives typically range from $25 to $50 per kilowatt reduced during peak events, with some programs offering higher rates during critical peak periods. Commercial customers can also benefit from dynamic pricing programs, where rates vary based on grid demand, enabling substantial savings through strategic load management.

For maximum benefit, businesses should evaluate multiple program options and consider stacking compatible incentives. Many utilities also provide free energy audits and technical assistance to help customers optimize their demand response strategies and maximize financial returns.

Smart Grid Technologies for Solar Integration

Advanced Metering Infrastructure

Advanced Metering Infrastructure (AMI) serves as the backbone of modern demand response programs, providing real-time data communication between utilities and consumers. Smart meters, the cornerstone of AMI, enable two-way communication and precise energy consumption monitoring, which is essential to modernize the electric grid.

These sophisticated monitoring systems collect and transmit data at intervals as frequent as every 15 minutes, offering unprecedented visibility into energy usage patterns. For facility managers and business owners, this granular data provides valuable insights into consumption behaviors, peak demand periods, and opportunities for cost savings.

Key components of AMI include:

– Smart meters with built-in communication capabilities

– Data management systems for processing and analyzing usage information

– Secure networks for transmitting data between utilities and consumers

– User interfaces for monitoring and managing energy consumption

The implementation of AMI delivers significant benefits:

– Real-time pricing information enables informed decision-making

– Automated demand response participation reduces operational complexity

– Enhanced accuracy in billing and usage tracking

– Faster outage detection and response

– Improved load forecasting capabilities

For businesses participating in demand response programs, AMI provides the tools necessary to verify performance and quantify financial returns, making it easier to justify and optimize energy management investments.

Automated Control Systems

Modern demand response systems rely heavily on sophisticated automated control systems that seamlessly manage energy consumption across facilities. These smart controllers integrate with building management systems (BMS) and utilize advanced algorithms to optimize load distribution based on real-time grid conditions and pricing signals.

At the core of these systems are intelligent load controllers that can automatically adjust HVAC systems, lighting, and other power-intensive equipment. Through real-time performance tracking and predictive analytics, these controllers can make split-second decisions to reduce demand during peak periods while maintaining optimal operational conditions.

Load management technology has evolved to include features such as automated load shedding, dynamic load prioritization, and intelligent peak prediction. These systems can identify non-essential loads that can be temporarily reduced or shifted to off-peak hours, ensuring minimal impact on business operations while maximizing demand response benefits.

Modern control systems also facilitate two-way communication between utilities and consumers, enabling automated participation in demand response events. When grid operators signal the need for load reduction, these systems can automatically implement pre-programmed response strategies, eliminating the need for manual intervention and ensuring consistent participation in demand response programs.

Integration capabilities with existing building automation systems make implementation straightforward, while user-friendly interfaces allow facility managers to monitor and adjust response parameters as needed.

Implementation Strategies

Load Assessment and Planning

Effective load assessment and planning form the foundation of a successful demand response program. The process begins with a comprehensive audit of your facility’s energy consumption patterns, identifying both essential and non-essential loads that can be adjusted during peak demand periods.

Start by categorizing loads into three tiers: critical loads that must remain operational, flexible loads that can be temporarily reduced, and deferrable loads that can be shifted to off-peak hours. Common flexible loads include HVAC systems, refrigeration units, and certain manufacturing processes. Deferrable loads might include batch processing operations, electric vehicle charging, or water heating systems.

To prioritize controllable loads, consider factors such as:

– Impact on operations and occupant comfort

– Equipment cycling capabilities

– Energy consumption patterns

– Response time requirements

– Associated cost savings potential

Modern building management systems and smart meters provide valuable data for load assessment. These systems track energy usage in real-time, helping identify peak consumption periods and opportunities for load shifting. Advanced analytics tools can simulate various demand response scenarios, enabling facility managers to optimize their load reduction strategies.

When developing your load management plan, establish clear protocols for:

– Load reduction sequences

– Communication procedures

– Emergency override capabilities

– Performance monitoring

– Staff training requirements

Regular reassessment of load priorities is essential as operational needs change and new technologies become available. Consider seasonal variations in energy usage and adjust your load management strategy accordingly. This systematic approach ensures maximum participation benefits while maintaining operational integrity during demand response events.

Integration with Existing Solar Systems

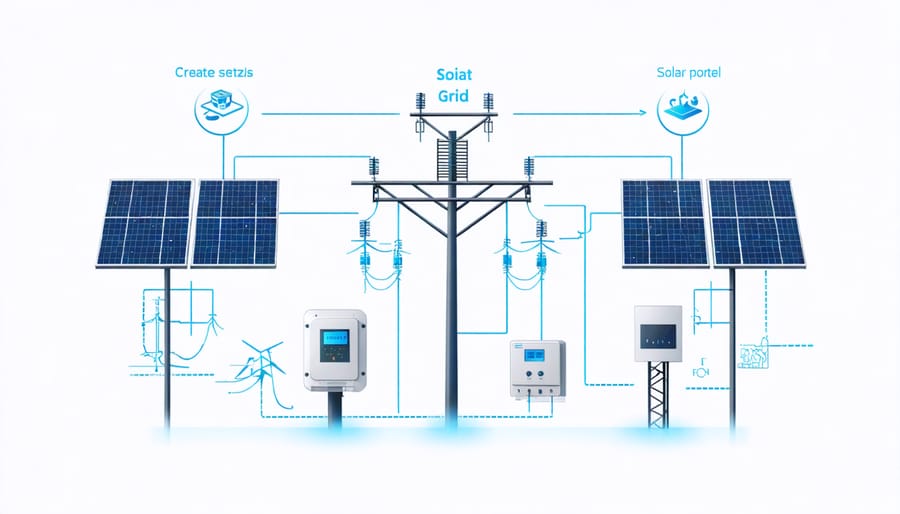

Integrating demand response systems with existing solar installations requires careful consideration of both technical specifications and operational parameters. Modern smart grid technology enables seamless communication between solar inverters, energy storage systems, and demand response controls.

Key integration components include advanced metering infrastructure (AMI), energy management systems (EMS), and automated load controllers. These systems work together to optimize solar generation, storage utilization, and load management based on real-time grid conditions and electricity pricing signals.

For successful integration, facility managers should consider:

1. Inverter compatibility with demand response protocols

2. Energy storage capacity and response time

3. Load prioritization and automation capabilities

4. Communication protocols between systems

5. Data monitoring and analytics requirements

Many commercial facilities have achieved significant cost savings through integrated solar and demand response systems. For example, a manufacturing facility in California reduced its peak demand charges by 35% by implementing automated load shifting during high solar generation periods.

To maximize ROI, businesses should:

– Conduct comprehensive energy audits

– Install compatible monitoring systems

– Implement automated controls

– Establish clear operational protocols

– Regular system maintenance and updates

The integration process typically requires collaboration between solar installers, utility providers, and demand response program administrators. This ensures all systems work harmoniously while meeting grid requirements and program specifications.

Success metrics should include peak demand reduction, solar self-consumption rates, and overall energy cost savings to validate the integration’s effectiveness.

Real-World Success Stories

Manufacturing Facility Case Study

A recent implementation at the Johnson Manufacturing Complex in Michigan demonstrates the significant impact of demand response smart grid systems in industrial settings. The facility, which operates 24/7 and consumes approximately 12 megawatts of power during peak production, achieved a 23% reduction in energy costs within the first year of implementation.

The system utilizes advanced metering infrastructure and automated load-shedding protocols, allowing the facility to participate in utility demand response programs while maintaining critical operations. During peak demand events, non-essential equipment automatically powers down in a coordinated sequence, reducing the facility’s load by up to 3.5 megawatts without impacting production schedules.

Key results from the implementation include:

– Annual energy cost savings of $875,000

– Additional utility incentives totaling $150,000

– 15% reduction in peak demand charges

– ROI achieved in 18 months

– Carbon emissions reduced by 2,800 metric tons annually

The facility’s success has led to the adoption of similar systems across the company’s other manufacturing locations. The automated nature of the response system has eliminated the need for manual intervention during demand events, ensuring consistent participation and maximizing financial benefits. Plant managers report improved grid reliability and enhanced energy awareness among staff as additional benefits of the implementation.

Commercial Office Building Example

A 15-story commercial office building in downtown Chicago demonstrates the significant impact of demand response implementation in smart grid systems. The property management company integrated an automated demand response system that monitors and adjusts energy consumption across HVAC, lighting, and auxiliary power systems.

During peak demand periods, the building automatically reduces its power consumption by adjusting temperature setpoints, dimming non-essential lighting, and cycling non-critical equipment. The system maintains tenant comfort while achieving substantial energy reductions through strategic load shifting and automated control strategies.

The results have been impressive: the building achieved a 22% reduction in peak demand charges and realized annual energy cost savings of $147,000. During critical peak events, the facility successfully reduced its load by up to 450 kW within 30 minutes of receiving utility signals.

Key success factors included:

– Advanced building automation system integration

– Real-time energy monitoring and analytics

– Customized reduction strategies for different zones and tenant types

– Clear communication protocols with occupants

– Regular performance optimization and adjustment

The implementation cost of $285,000 was recovered within 23 months through utility incentives and energy savings. Additionally, the building earned ENERGY STAR certification and enhanced its market position as a sustainable property, leading to increased tenant satisfaction and retention rates. This example demonstrates how commercial buildings can leverage demand response programs to achieve both environmental and financial benefits while maintaining occupant comfort.

Demand response smart grid technology represents a pivotal advancement in modern energy management, offering substantial benefits for businesses, utilities, and the environment. By implementing these systems, organizations can achieve average energy cost reductions of 15-30% while contributing to grid stability and sustainability goals. The proven ROI, coupled with increasing regulatory incentives, makes demand response integration a strategic priority for forward-thinking enterprises.

To successfully implement demand response programs, organizations should begin by conducting comprehensive energy audits and identifying flexible loads. Working with qualified service providers, facility managers can develop customized strategies that align with their operational requirements. Investment in smart meters, building automation systems, and energy management software will create the foundation for effective demand response participation.

The future of demand response looks particularly promising as grid modernization continues and renewable energy integration expands. Organizations that act now will be well-positioned to capitalize on emerging opportunities, including dynamic pricing programs and automated demand response systems. By establishing clear implementation timelines, securing stakeholder buy-in, and maintaining regular program evaluation, businesses can maximize the benefits of their demand response initiatives.

The transition to smart grid technology and demand response programs represents not just an operational upgrade, but a strategic investment in future-ready infrastructure. As energy markets evolve and grid pressures increase, demand response will become increasingly vital for maintaining reliability and controlling costs.