In the race to combat climate change and optimize operational costs, green energy innovations are revolutionizing how businesses power their future. Recent breakthroughs in renewable technology have made sustainable energy solutions more accessible, efficient, and commercially viable than ever before. From advanced solar capture systems achieving 40% greater efficiency to AI-driven smart grids that reduce energy waste by up to 30%, these innovations are transforming industrial energy landscapes worldwide.

Leading corporations have already demonstrated the tangible benefits of adopting green energy solutions, with average ROI periods shortening from 8-10 years to just 3-5 years. Tesla’s Gigafactory, powered entirely by renewable energy, showcases how large-scale manufacturing can operate sustainably while maintaining peak production efficiency. Similarly, Google’s achievement of carbon-neutral operations through innovative energy management systems proves that environmental responsibility and business growth can coexist harmoniously.

As global markets increasingly prioritize sustainability, businesses implementing these cutting-edge solutions gain competitive advantages through reduced operational costs, enhanced brand reputation, and improved regulatory compliance. The convergence of technological advancement, economic viability, and environmental necessity has created an unprecedented opportunity for organizations to lead in the green energy revolution.

Revolutionary Solar Integration Technologies

Smart Solar Tracking Systems

Smart solar tracking systems represent a significant advancement in maximizing your solar investment through intelligent panel positioning technology. These sophisticated systems utilize precision motors and advanced algorithms to continuously adjust solar panels throughout the day, following the sun’s path to optimize energy capture.

Industrial facilities implementing these tracking systems typically see 25-35% higher energy yield compared to fixed installations. The technology employs dual-axis tracking capabilities, allowing panels to move both horizontally and vertically to maintain optimal solar exposure from dawn to dusk.

Modern tracking systems feature weather-adaptive programming that responds to environmental conditions in real-time. During high winds, panels automatically adjust to safe positions, while cloud-detection algorithms optimize energy capture during varying weather conditions. These smart features significantly reduce maintenance requirements while extending system longevity.

Recent installations at manufacturing facilities demonstrate the practical benefits: a 500kW system with tracking technology in Melbourne achieved 32% higher annual energy production compared to traditional fixed arrays, with a payback period reduced by two years. The integration of IoT sensors and predictive maintenance protocols ensures consistent performance while minimizing operational costs.

Industrial-Scale Energy Storage Solutions

The evolution of industrial energy storage solutions has revolutionized how businesses manage and utilize renewable energy resources. Modern battery technologies, particularly lithium-ion systems and flow batteries, now enable facilities to store multiple megawatt-hours of power, ensuring consistent energy supply during peak demand periods and weather-related interruptions.

Leading manufacturers have developed scalable storage systems that integrate seamlessly with existing power infrastructure, offering modular designs that can be expanded as energy needs grow. These systems feature advanced battery management technology, thermal regulation, and predictive maintenance capabilities, significantly reducing operational risks and maintenance costs.

Recent implementations in manufacturing facilities and data centers demonstrate impressive results, with some organizations reporting up to 40% reduction in peak energy costs and achieving 99.9% power reliability. The integration of smart grid technology with these storage systems allows for automated demand response, enabling businesses to optimize energy consumption patterns and capitalize on time-of-use pricing advantages.

For facility managers considering implementation, modern storage solutions offer typical ROI periods of 5-7 years, with systems designed to maintain 80% capacity for up to 20 years. This longevity, combined with decreasing installation costs and improved energy density, makes industrial-scale storage an increasingly attractive investment for sustainable operations.

Process Heat Innovation

Solar Thermal Systems

Solar thermal systems are revolutionizing manufacturing processes by harnessing the sun’s energy to generate heat for industrial applications. These systems utilize specialized collectors and heat transfer fluids to capture solar radiation, converting it into thermal energy that can be used for various manufacturing operations, including process heating, steam generation, and drying.

A notable implementation can be found at the Valencia Food Processing Facility, where solar thermal collectors provide up to 60% of the heat required for their sterilization processes, resulting in a 45% reduction in annual energy costs. This successful case demonstrates the technology’s potential for industries with high thermal energy demands.

The integration of solar thermal systems typically involves three key components: solar collectors, heat storage systems, and heat distribution networks. Modern installations often feature advanced tracking systems that maximize solar exposure throughout the day, ensuring optimal energy capture and consistent heat supply.

For manufacturing facilities, the benefits extend beyond environmental impact. Companies report average payback periods of 3-5 years, with systems lasting 20-25 years. Additionally, government incentives and carbon credits can significantly reduce initial investment costs, making solar thermal solutions increasingly attractive for industrial applications.

Temperature requirements ranging from 80°C to 400°C can be met through various solar thermal technologies, including flat-plate collectors for lower temperatures and concentrated solar power systems for high-temperature applications. This versatility makes solar thermal systems adaptable to diverse manufacturing needs while providing a reliable, sustainable energy source.

Heat Recovery Systems

Heat recovery systems represent a significant advancement in energy efficiency by capturing and repurposing waste heat from industrial processes, HVAC systems, and power generation. These innovative systems seamlessly integrate with renewable energy sources to create comprehensive energy solutions that maximize resource utilization and reduce operational costs.

Modern heat recovery systems employ sophisticated heat exchangers and thermal storage technologies to capture waste heat from various sources, including manufacturing processes, data centers, and building exhaust systems. This recovered energy can be redirected to multiple applications, such as preheating water, space heating, or powering absorption chillers for cooling needs.

When combined with renewable energy sources, heat recovery systems create powerful synergies. For example, solar thermal installations can work in tandem with heat recovery units to maintain consistent temperature levels in industrial processes, while excess heat from biomass systems can be captured and utilized for additional applications.

A notable case study from a European manufacturing facility demonstrated that implementing an integrated heat recovery system resulted in a 40% reduction in energy costs and a 30% decrease in carbon emissions. The system paid for itself within three years through reduced energy consumption and operational savings.

For facility managers and business owners, heat recovery systems offer a practical pathway to improved energy efficiency and sustainability. The technology’s adaptability to various industrial settings, combined with its proven ROI, makes it an essential component of modern green energy strategies.

Smart Grid Integration

Load Management Systems

Modern load management systems represent a significant advancement in green energy optimization, enabling organizations to precisely control and distribute power consumption across their facilities. These intelligent systems utilize real-world data and predictive analytics to balance energy demand, reducing peak loads and associated costs while maximizing the efficiency of renewable energy sources.

Through integration with smart building retrofits, load management technologies can automatically adjust power consumption based on real-time grid conditions, energy pricing, and facility demands. Advanced features include automated load shedding during peak periods, dynamic rate optimization, and seamless integration with on-site renewable energy systems.

Industry leaders implementing these systems typically report 15-30% reductions in energy costs, with some achieving payback periods as short as 18-24 months. For example, a major Australian manufacturing facility reduced its peak demand charges by 22% in the first year after implementing load management technology integrated with their solar installation.

The latest systems also incorporate machine learning capabilities to optimize performance continuously, ensuring maximum efficiency while maintaining operational reliability and occupant comfort.

Real-time Monitoring Solutions

Real-time monitoring solutions have revolutionized energy management by providing unprecedented visibility into consumption patterns and system performance. These digital platforms integrate advanced sensors, IoT devices, and sophisticated analytics software to deliver actionable insights for energy optimization.

Modern monitoring systems track key metrics including power generation, consumption rates, and equipment efficiency in real-time. Facility managers can access detailed dashboards showing energy flow patterns, peak usage periods, and potential system anomalies through user-friendly interfaces. This immediate feedback enables quick response to inefficiencies and proactive maintenance scheduling.

The implementation of AI-driven monitoring solutions has demonstrated energy savings of 15-30% in commercial settings. These systems can automatically adjust energy distribution based on demand patterns, weather conditions, and time-of-use pricing. For example, a manufacturing facility in Germany reduced its energy costs by 22% within six months of implementing smart monitoring technology.

Cloud-based platforms now enable remote monitoring and control, allowing facility managers to optimize energy usage across multiple locations from a central dashboard. This technological advancement has become particularly valuable for businesses with distributed operations seeking to maintain consistent energy efficiency standards across their facilities.

ROI and Implementation Success Stories

Manufacturing Sector Case Study

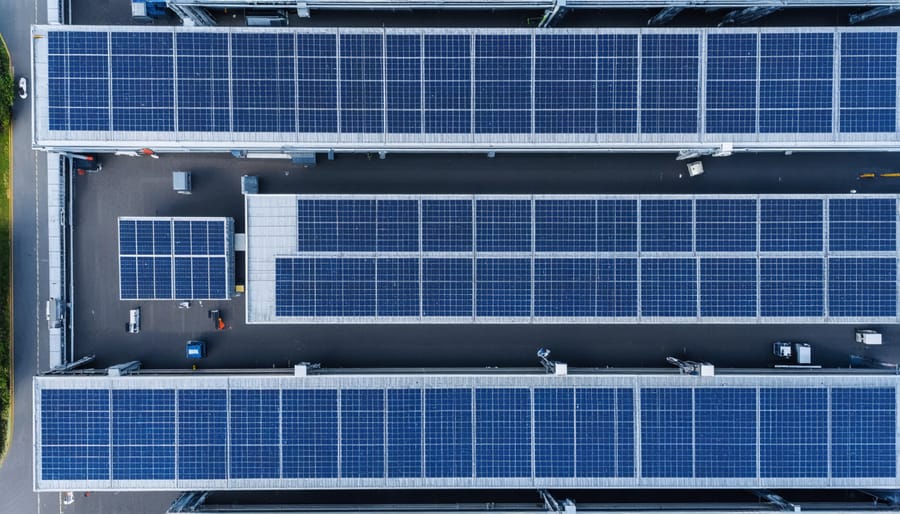

A leading automotive parts manufacturer in Stuttgart successfully transformed its energy infrastructure through comprehensive renewable integration, achieving remarkable results within 18 months of implementation. The facility, spanning 50,000 square meters, installed a 2.5MW solar array combined with smart energy storage systems and AI-driven energy management software.

The integration process began with a detailed energy audit that identified peak usage patterns and optimization opportunities. The manufacturer implemented a three-phase approach: first installing rooftop solar panels, then adding battery storage systems, and finally deploying smart grid technology to manage power distribution efficiently.

Key achievements include:

– 45% reduction in annual energy costs

– 60% decrease in carbon emissions

– 30% improvement in energy efficiency

– ROI achieved in 4.2 years

The facility now generates 65% of its daily power requirements through renewable sources, with excess energy stored for use during peak demand periods. The smart management system automatically adjusts production schedules to maximize solar power utilization, resulting in optimal energy consumption patterns.

This successful implementation has become a blueprint for other manufacturing facilities, demonstrating how strategic renewable energy integration can deliver both environmental and financial benefits while maintaining operational efficiency.

Food Processing Industry Example

A leading Italian pasta manufacturer demonstrates the transformative potential of green energy innovations in food processing. In 2021, the company invested €2.8 million in a comprehensive solar installation and energy optimization system, yielding remarkable results within 18 months of implementation.

The facility installed a 1.2MW rooftop solar array combined with smart energy management systems and heat recovery solutions. This integrated approach allowed them to capture and repurpose thermal energy from production processes while generating clean electricity for operations.

Key performance metrics showcase the project’s success:

– 42% reduction in overall energy costs

– ROI achieved in 3.2 years

– 68% decrease in carbon emissions

– Annual energy savings of €580,000

– Production efficiency increased by 15%

The system’s intelligent monitoring platform optimizes energy usage during peak production hours, while excess energy generated during weekends is stored or fed back to the grid. The company also implemented LED lighting and variable-speed drives for motors, further enhancing energy efficiency.

This success story has become a blueprint for other food processors, demonstrating how green energy innovations can deliver both environmental and financial benefits while maintaining product quality and operational reliability.

Future-Proofing Industrial Energy Systems

The industrial sector is witnessing a transformative shift toward sustainable energy systems, driven by technological advancements and the pressing need for environmental responsibility. Smart microgrids are emerging as a cornerstone of future-proof industrial energy infrastructure, enabling facilities to seamlessly integrate multiple renewable sources while maintaining operational reliability.

Advanced energy storage solutions are revolutionizing how industries manage power consumption. Flow batteries and thermal storage systems are providing unprecedented flexibility in energy management, allowing facilities to store excess renewable energy during peak production periods and utilize it during high-demand times or emergencies.

Artificial Intelligence and machine learning algorithms are optimizing energy consumption patterns in real-time. These systems analyze vast amounts of operational data to predict energy needs, adjust production schedules, and maximize renewable energy utilization. For instance, a manufacturing facility in Germany implemented AI-driven energy management, resulting in a 25% reduction in energy costs and a 30% increase in renewable energy usage.

Industrial Internet of Things (IIoT) sensors and smart meters are creating interconnected energy ecosystems. These devices provide granular insights into energy consumption patterns, enabling facility managers to identify inefficiencies and optimize resource allocation. A recent case study of a food processing plant demonstrated how IIoT integration led to a 40% improvement in energy efficiency within the first year.

Hybrid renewable systems are gaining traction, combining solar, wind, and other renewable sources to ensure consistent power supply. These systems often incorporate advanced power electronics and control systems that automatically switch between energy sources based on availability and demand.

Looking ahead, emerging technologies like green hydrogen production and carbon capture systems are poised to further transform industrial energy landscapes. Companies investing in these future-proof solutions are not only reducing their environmental impact but also gaining competitive advantages through reduced operational costs and enhanced energy security.

To ensure successful implementation, industries are adopting phased approaches to energy system modernization, allowing for systematic integration of new technologies while maintaining operational continuity. This strategic approach helps minimize disruption while maximizing the benefits of renewable energy integration.

The transition to renewable energy represents a pivotal opportunity for industries to achieve both environmental sustainability and economic growth. By implementing green energy solutions, organizations can reduce operational costs by 30-50% while significantly decreasing their carbon footprint. The key benefits extend beyond financial savings to include enhanced brand reputation, regulatory compliance, and increased operational resilience. To begin the renewable energy journey, industries should first conduct comprehensive energy audits, engage with experienced renewable energy consultants, and develop phased implementation plans. Setting clear sustainability targets, securing stakeholder buy-in, and exploring available government incentives are crucial steps toward successful integration. As green technologies continue to advance and become more cost-effective, organizations that act now will position themselves as industry leaders while contributing to a more sustainable future.