In today’s high-stakes business environment, responding swiftly and effectively to solar system incidents can mean the difference between minimal disruption and catastrophic failure. Understanding and managing critical solar safety risks requires a structured, systematic approach that protects both assets and personnel.

The five-step incident response framework has become the industry standard for managing solar emergencies, from minor inverter malfunctions to major system failures. This methodology, endorsed by leading energy security experts and facility management professionals, ensures organizations can detect, contain, and resolve incidents while maintaining operational continuity.

Whether you’re developing a new incident response plan or strengthening existing protocols, understanding these five essential steps will equip your team with the tools needed to handle any solar system emergency efficiently and professionally. By implementing this framework, organizations can significantly reduce downtime, minimize financial impact, and maintain their solar infrastructure’s integrity.

Let’s examine the critical steps that form the backbone of effective incident response management in commercial solar installations.

1. Identification and Initial Assessment

Monitoring System Alerts

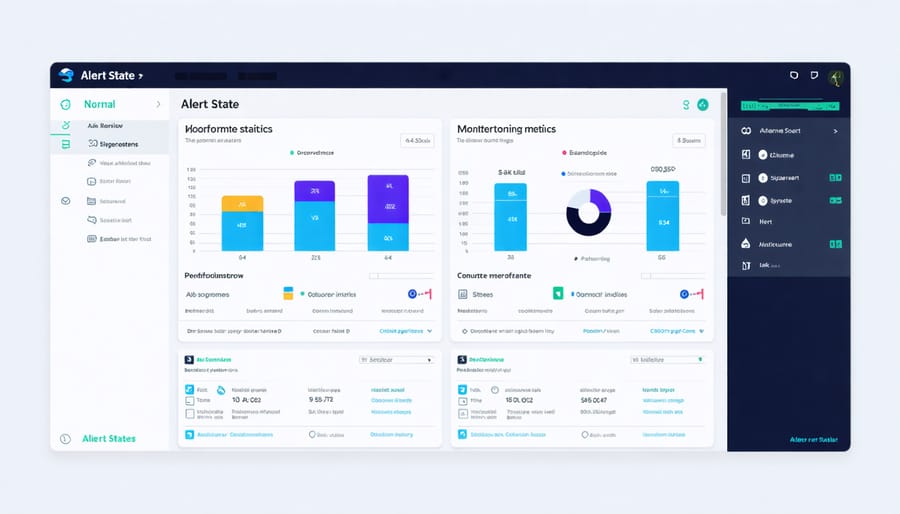

Effective incident response begins with robust smart monitoring systems that provide real-time oversight of your solar installation’s performance and safety parameters. These automated systems continuously track key metrics such as power output, voltage levels, temperature readings, and equipment status, generating immediate alerts when deviations occur.

Modern monitoring platforms utilize advanced algorithms to detect anomalies and categorize alerts based on severity levels. Critical alerts, such as sudden power drops or equipment malfunctions, trigger immediate notifications through multiple channels, including email, SMS, and mobile app push notifications. This ensures that responsible personnel are informed promptly, enabling swift response to potential incidents.

To maximize the effectiveness of monitoring systems, facility managers should establish clear alert thresholds and escalation protocols. Parameters should be calibrated to minimize false positives while ensuring genuine issues are caught early. Regular system checks and updates are essential to maintain monitoring accuracy and reliability.

Alert configurations should be customized based on:

– Historical performance data

– Seasonal variations

– Site-specific requirements

– Regulatory compliance needs

– Equipment manufacturer specifications

This comprehensive monitoring approach enables proactive incident management, reducing downtime and protecting your solar investment through early detection and rapid response capabilities.

Initial Safety Protocols

When responding to a solar system incident, the first priority is ensuring the safety of all personnel and securing the affected area. Begin by conducting a rapid visual assessment from a safe distance to identify any obvious hazards such as electrical arcing, smoke, or structural damage. Immediately establish a safety perimeter and restrict access to authorized personnel only.

Personnel must don appropriate Personal Protective Equipment (PPE) before approaching the incident site. This typically includes insulated gloves, safety glasses, and arc-flash rated clothing. If the incident involves fire or electrical hazards, notify emergency services immediately and do not attempt to access the area until professional first responders arrive.

Proceed with documenting initial observations, including visible damage, environmental conditions, and any warning indicators that preceded the incident. Check monitoring systems for alerts or performance anomalies that might provide insight into the cause. If safe to do so, identify and record the status of key system components such as inverters, disconnect switches, and monitoring equipment.

Verify that the site’s emergency shutdown procedures are readily accessible and that all team members are familiar with their roles. Review site-specific safety protocols and ensure that emergency contact information is current and visible. During this initial phase, avoid making any system adjustments unless absolutely necessary to prevent immediate danger or further damage.

Finally, establish a clear chain of command for the incident response and designate a primary point of contact for communication with stakeholders and emergency services.

2. Containment Strategies

Emergency Shutdown Procedures

In the event of a critical incident, executing a proper emergency shutdown is crucial for maintaining system integrity and personnel safety. Begin by following established safety compliance procedures while assessing the situation’s severity.

First, activate the emergency stop button if immediate shutdown is required. This cuts power to all major system components simultaneously. Next, initiate the systematic shutdown sequence through your monitoring system interface, ensuring all active processes are properly terminated.

Verify that the main AC disconnect switch is in the “OFF” position, followed by disengaging all DC disconnects from the solar array strings. Document each step taken during the shutdown process, including timestamps and any observed anomalies.

Once power flow has ceased, secure the facility perimeter and place appropriate warning signage. Contact your designated emergency response team and solar system maintenance provider immediately.

Remember to maintain communication with all stakeholders throughout the shutdown process, and only attempt system restart after receiving clearance from qualified personnel who have thoroughly assessed and addressed the incident’s root cause.

Isolation Protocols

Once an incident is detected, swift isolation of affected components is crucial to prevent further damage and protect the overall system integrity. Begin by identifying the specific components involved in the incident, whether they’re inverters, panels, or monitoring systems. Immediately disconnect these components from the main power supply using the emergency shutdown procedures outlined in your system documentation.

For networked systems, implement network segmentation to isolate affected devices from the rest of your infrastructure. This may involve disabling network ports, adjusting firewall rules, or physically disconnecting network cables. Document each isolation action taken, including timestamps and specific components affected, to maintain a clear audit trail.

Create a containment perimeter around affected areas, especially in cases involving physical damage or environmental hazards. Use appropriate barriers and warning signage to prevent unauthorized access. If the incident involves data systems, implement additional authentication measures and temporarily restrict user access to potentially compromised accounts or systems.

Ensure that isolation measures don’t inadvertently affect critical operations or safety systems. Maintain essential services through redundant systems where possible, and communicate isolation protocols clearly to all relevant stakeholders. Regular testing of isolation procedures during non-emergency periods helps ensure their effectiveness when needed.

3. Damage Assessment and Documentation

Technical Inspection Checklist

A thorough technical inspection is essential for assessing and documenting the extent of any solar system incident. Begin by conducting a visual examination of all system components, including panels, inverters, wiring, and mounting structures. Document any visible damage using high-resolution photographs from multiple angles, ensuring proper lighting and clear focus.

Create a detailed checklist that includes voltage measurements at key connection points, thermal imaging scans to identify potential hot spots, and performance data comparison with baseline metrics. Test all safety systems, including emergency shut-off mechanisms and monitoring equipment, to ensure they’re functioning correctly.

Record specific observations about environmental conditions at the time of the incident, such as weather patterns, temperature, and any external factors that may have contributed to the situation. Include time stamps and GPS coordinates where applicable.

Maintain a comprehensive log of all inspection findings, including:

– Component serial numbers

– Performance measurements

– Deviation from normal operating parameters

– Safety system status

– Structural integrity assessment

– Electrical connection quality

– Communication system functionality

This documentation serves as crucial evidence for insurance claims, warranty issues, and future preventive measures. Store all inspection records securely and make them readily accessible to authorized personnel for reference and analysis.

Insurance and Compliance Documentation

Maintaining comprehensive documentation throughout the incident response process is crucial for insurance claims and regulatory compliance. Every incident should be recorded in a standardized incident report format, including detailed descriptions of the event, immediate actions taken, and outcomes. Document all damages with photographs, timestamps, and written assessments from qualified personnel.

Keep a chronological log of all communications with emergency responders, insurance representatives, and relevant stakeholders. This documentation should include names, contact information, and summaries of discussions. Preserve any surveillance footage, sensor data, or system logs that might provide context about the incident’s cause and progression.

For insurance purposes, maintain detailed records of repair costs, replacement equipment, and any business interruption losses. Include copies of invoices, work orders, and contractor assessments. Document any temporary measures implemented and their associated costs.

Create a separate file for compliance-related documentation, including permits, inspection reports, and correspondence with regulatory bodies. This ensures you can demonstrate due diligence in following safety protocols and industry standards. Store all documentation securely, with both physical and digital copies, and ensure accessibility to authorized personnel while maintaining confidentiality requirements.

4. System Recovery and Repair

Component Replacement Guidelines

When replacing damaged components in a solar energy system, follow a systematic approach to ensure safety and system integrity. Begin by conducting a thorough assessment of the damaged component and documenting its specifications, including model numbers and technical requirements. Always source replacement parts from authorized manufacturers or certified distributors to maintain warranty coverage and system compatibility.

Before initiating replacement procedures, shut down the affected system section following proper lockout/tagout protocols. Ensure all necessary replacement tools and equipment are readily available, and verify that replacement personnel have appropriate certifications and safety gear.

For critical components such as inverters or control systems, consider having redundant parts on standby to minimize system downtime. Maintain detailed records of all replacements, including serial numbers, installation dates, and testing results. This documentation is essential for warranty claims and future maintenance planning.

After installation, perform comprehensive testing to verify proper functionality and integration with existing systems. Monitor the replaced component’s performance for at least 24 hours to ensure stability. Update system documentation and maintenance schedules to reflect the new component’s specifications and requirements.

Consider implementing a preventive maintenance program to identify potential component failures before they occur, reducing unexpected downtime and replacement costs. Regular inspections and performance monitoring can significantly extend component life and improve system reliability.

System Testing and Validation

After implementing repairs and resolving the initial incident, thorough system testing and validation are crucial to ensure the solar installation returns to optimal performance. Begin with a comprehensive diagnostic scan of all affected components, including inverters, monitoring systems, and electrical connections. Document baseline readings for voltage, current, and power output to compare against pre-incident performance metrics.

Conduct sequential testing of each subsystem, starting with safety mechanisms such as emergency shutdown controls and ground fault protection. Verify that monitoring and alert systems are properly recalibrated and communicating accurately with central control systems. This includes testing all sensor inputs and ensuring data logging functions are operational.

Performance validation should include both no-load and full-load testing scenarios to confirm system stability under various operating conditions. Monitor key parameters such as conversion efficiency, temperature readings, and power quality metrics for at least 24-48 hours post-repair. Any anomalies during this period warrant immediate investigation and potential adjustments.

Document all test results, including time stamps, environmental conditions, and specific performance indicators. Create a detailed validation report comparing current system performance against manufacturer specifications and historical data. This documentation serves as both proof of proper system restoration and baseline reference for future maintenance activities.

Finally, schedule a follow-up inspection within 30 days to verify long-term stability and identify any potential delayed effects from the incident.

5. Post-Incident Analysis and Prevention

Root Cause Analysis

Root cause analysis involves systematically investigating the underlying factors that led to the solar system incident. Begin by gathering all available data, including system logs, maintenance records, and witness accounts. Create a detailed timeline of events leading up to the incident, identifying any deviations from normal operations. Use proven analysis methods such as the “5 Whys” technique or Ishikawa diagrams to trace the incident back to its source.

Document all findings and implement corrective actions to prevent similar incidents. This might include updating maintenance schedules, revising operating procedures, or upgrading equipment components. Regular review of these preventive measures ensures their continued effectiveness and helps maintain system reliability. Remember that thorough root cause analysis not only resolves current issues but also strengthens overall system resilience.

System Optimization Recommendations

To enhance system resilience and prevent system vulnerabilities, implement regular security audits and automated monitoring solutions. Establish redundant power backup systems and maintain up-to-date firmware across all solar components. Deploy advanced monitoring tools that provide real-time performance metrics and early warning indicators. Consider implementing AI-driven predictive maintenance protocols to identify potential issues before they escalate into incidents. Strengthen access controls through multi-factor authentication and role-based permissions. Regular staff training on security protocols and incident response procedures is essential for maintaining system integrity. Document all system configurations and maintain detailed recovery procedures for quick response during emergencies.

Effective incident response planning is crucial for maintaining the reliability and safety of your solar energy system. By following these five essential steps – identification, containment, eradication, recovery, and lessons learned – organizations can minimize downtime, protect assets, and ensure business continuity. Remember that successful incident response requires regular team training, clear communication channels, and up-to-date documentation. Investing time in developing and maintaining a comprehensive incident response plan not only safeguards your solar installation but also demonstrates commitment to operational excellence. Regular reviews and updates of your response protocols, combined with periodic drills, will keep your team prepared for any challenges that may arise. Make incident response planning a priority to protect your renewable energy investment and maintain stakeholder confidence.