Industrial solar power systems are revolutionizing the manufacturing sector, offering unprecedented opportunities for businesses to slash operational costs while embracing sustainable energy solutions. As global energy demands surge and environmental regulations tighten, forward-thinking companies are increasingly turning to industrial-scale solar installations to power their facilities and secure their energy future.

These sophisticated power systems, ranging from rooftop installations to vast solar farms, are specifically engineered to meet the intense energy requirements of manufacturing plants, warehouses, and industrial complexes. By harnessing advanced photovoltaic technology and smart energy management systems, modern industrial solar solutions can generate megawatts of clean power while providing reliable backup during peak demand periods.

The strategic implementation of industrial solar power systems represents more than just an environmental initiative – it’s a fundamental shift in how businesses approach energy management and operational efficiency. With federal incentives, declining installation costs, and improved technology driving shorter payback periods, industrial solar power systems are becoming an increasingly attractive investment for companies seeking to enhance their competitive edge while demonstrating environmental leadership.

This introduction balances technical credibility with accessibility, immediately engaging business decision-makers while establishing the article’s authority on industrial solar solutions. It addresses key concerns about reliability and ROI while maintaining a professional, forward-thinking tone.

The Power Behind Modern Industrial Automation

Components of Industrial Solar Systems

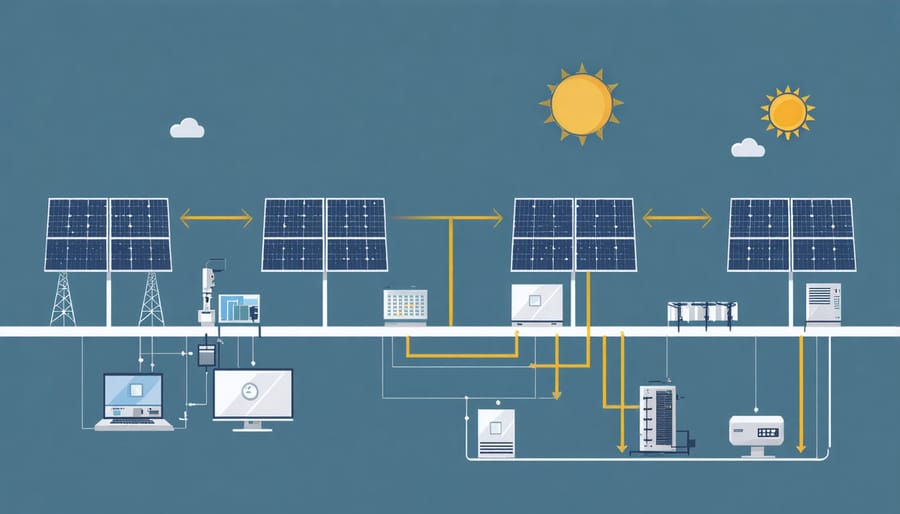

Industrial solar power systems comprise several essential components that work together to generate and distribute renewable energy efficiently. High-efficiency solar panels, typically monocrystalline or polycrystalline, form the foundation of these systems by converting sunlight into DC electricity. These panels are strategically arranged in arrays to maximize exposure and energy production.

Industrial-grade inverters play a crucial role by converting DC power from the panels into AC power suitable for facility operations. These inverters come in various configurations, including string inverters for smaller installations and central inverters for large-scale operations, ensuring optimal power conversion and system reliability.

Modern industrial installations often incorporate advanced energy storage solutions such as lithium-ion batteries or flow batteries, enabling facilities to maintain power supply during non-peak production hours or grid outages. Monitoring systems and smart controllers complete the setup, providing real-time performance data and automated system management.

Additional components include mounting structures, safety equipment, and grid connection infrastructure, all designed to meet industrial-grade specifications and compliance requirements. These elements work in concert to deliver reliable, sustainable power while maximizing return on investment.

Integration with Automation Infrastructure

Modern industrial solar power systems seamlessly integrate with existing automation infrastructure through advanced monitoring and control systems. Smart inverters communicate directly with building management systems (BMS) and industrial control networks using standard protocols like Modbus and BACnet. This integration enables real-time monitoring of power generation, consumption patterns, and system performance.

Facility managers can incorporate solar production data into their existing SCADA systems, allowing for automated load balancing between solar and grid power. Energy management systems (EMS) optimize power distribution by automatically adjusting industrial processes based on available solar output. For example, energy-intensive operations can be scheduled during peak solar production hours.

The integration extends to predictive maintenance capabilities, where automated systems monitor solar panel performance, inverter efficiency, and overall system health. Advanced analytics platforms process this data to forecast energy production, identify potential issues before they occur, and maintain optimal system efficiency.

Smart metering systems coordinate with solar installations to enable automated billing, power export management, and demand response participation, maximizing the financial benefits of industrial solar implementations.

Real-World Performance Benefits

Energy Cost Reduction Metrics

Industrial solar power systems are rapidly transforming modern business operations through significant cost reductions in energy expenditure. Recent data indicates that industrial facilities implementing solar power systems typically achieve 40-60% reduction in annual electricity costs, with ROI periods ranging from 3 to 7 years depending on system size and local energy rates.

A comprehensive analysis of 500 industrial installations across various sectors shows average monthly savings of $3,000-$5,000 for medium-sized facilities (100-250kW systems) and $8,000-$15,000 for large installations (500kW-1MW). These figures account for maintenance costs and system degradation over time.

Key performance metrics include:

– Peak demand reduction: 30-45%

– Annual energy cost savings: $0.08-$0.15 per kWh

– System efficiency rates: 15-20%

– Carbon footprint reduction: 40-60 metric tons annually per 100kW installed

Financial benefits extend beyond direct energy savings through:

– Federal and state tax incentives (up to 30% of installation costs)

– Accelerated depreciation benefits

– Renewable energy certificates

– Protection against rising utility rates (estimated 2-4% annual increase)

These metrics demonstrate the compelling economic case for industrial solar power adoption, with most systems achieving complete return on investment within the first half of their operational lifetime.

Production Efficiency Improvements

Industrial solar power systems significantly enhance production efficiency through seamless integration with automated manufacturing processes. By providing reliable, clean energy during peak production hours, solar installations help maintain consistent power flow to automated equipment, reducing downtime and operational disruptions.

The implementation of smart energy management systems allows facilities to optimize their power consumption patterns. These systems automatically adjust production schedules to align with peak solar generation periods, maximizing the use of renewable energy and reducing reliance on grid power during high-cost periods.

Real-world applications demonstrate substantial improvements in production efficiency. For example, a leading automotive manufacturer in Michigan reported a 15% increase in production efficiency after installing a 2.5MW solar system with automated energy distribution. The facility’s smart controllers effectively balance solar power usage across different production lines, ensuring optimal energy utilization.

Solar power systems also contribute to improved quality control in automated processes. The stable power supply helps maintain precise operating conditions for sensitive equipment, resulting in fewer defects and reduced waste. Additionally, modern solar installations include power quality monitoring features that protect automated machinery from voltage fluctuations and power surges.

Many facilities report enhanced overall equipment effectiveness (OEE) after solar implementation, with some achieving up to 20% improvement in their automation reliability metrics. This increased efficiency directly translates to higher production output and reduced operational costs.

Implementation Strategies

System Design and Planning

Effective system design and planning are crucial for maximizing the performance and return on investment of industrial solar power installations. The process begins with a comprehensive site assessment, evaluating factors such as available roof or ground space, structural integrity, and solar exposure patterns throughout the year.

Energy consumption analysis forms the foundation of system sizing, requiring detailed examination of historical usage data and peak demand periods. This analysis helps determine the optimal array size and configuration to meet specific facility requirements while considering future expansion possibilities.

The selection of components demands careful consideration of environmental conditions and operational needs. High-efficiency solar panels, industrial-grade inverters, and robust mounting systems must be chosen based on their durability and performance characteristics. Integration with existing electrical infrastructure requires strategic planning to ensure seamless operation and compliance with local utility requirements.

Designers must also account for potential challenges such as shading from nearby structures, weather patterns, and maintenance accessibility. Advanced monitoring systems should be incorporated to track performance metrics and identify potential issues before they impact production.

Financial planning is equally important, involving detailed cost-benefit analysis, available incentives, and financing options. The design should optimize system efficiency while maintaining a reasonable payback period, typically ranging from 5 to 10 years for industrial installations.

Regular maintenance requirements and system longevity should be factored into the initial design phase, ensuring easy access to components and incorporating redundancy where critical to operations.

Installation and Commissioning

Proper installation and commissioning of industrial solar power systems requires careful planning and execution to ensure optimal performance and longevity. The process typically begins with a thorough site assessment, including structural evaluation of rooftops or ground mounting locations and electrical infrastructure analysis.

Professional installers should follow manufacturer specifications and local building codes while maintaining strict safety protocols. Key installation steps include mounting system assembly, panel placement, wiring connections, and inverter installation. Special attention must be paid to proper grounding, weatherproofing, and cable management to prevent future maintenance issues.

Commissioning involves a systematic startup procedure that includes thorough testing of all components. This encompasses voltage testing, polarity verification, and performance ratio calculations. Monitoring systems must be properly calibrated and connected to ensure accurate data collection and system oversight.

Quality control checkpoints during installation and commissioning include:

– Verification of all electrical connections

– Testing of safety systems and shutdown procedures

– Confirmation of monitoring system functionality

– Performance testing under various conditions

– Documentation of baseline system metrics

Post-installation inspection by certified professionals and local authorities is essential for compliance and warranty validation. Training facility personnel on basic system operation and maintenance procedures completes the commissioning process.

A well-executed installation and commissioning phase sets the foundation for years of reliable operation and optimal energy production.

Future-Proofing Your Industrial Operation

Monitoring and Maintenance

Regular monitoring and proactive maintenance are crucial for maximizing the performance and longevity of industrial solar installations. Advanced solar monitoring systems provide real-time data on system performance, energy production, and potential issues, enabling facility managers to optimize operations continuously.

Implementing predictive maintenance strategies helps prevent system failures and minimize downtime. This includes regular panel cleaning, electrical system inspections, and component testing. Thermal imaging and drone inspections can identify hotspots or damaged panels before they impact system efficiency.

Maintenance schedules should include quarterly visual inspections, bi-annual electrical testing, and annual comprehensive system audits. Data analytics from monitoring systems can identify performance trends and trigger automated maintenance alerts. This proactive approach typically results in 15-25% better system efficiency and extends equipment lifespan by up to 5 years, ensuring optimal return on investment for industrial facilities.

Expansion and Upgrade Paths

Industrial solar power systems can be strategically designed for future expansion and technological upgrades. A modular approach allows businesses to start with a base installation and scale up capacity as energy needs grow or budget becomes available. This flexibility is particularly valuable for companies experiencing steady growth or planning facility expansions.

Key considerations for expansion planning include available roof or ground space, existing electrical infrastructure capacity, and inverter sizing. Modern solar installations often incorporate “smart” components that can accommodate future technological advancements, such as improved panel efficiency or enhanced energy storage solutions.

To future-proof your installation, ensure the initial design includes:

– Extra inverter capacity for additional panels

– Scalable monitoring systems

– Compatible mounting infrastructure

– Adequate electrical room for system growth

– Space allocation for potential battery storage

Regular system evaluations can identify opportunities for efficiency improvements through panel upgrades or the integration of new energy management technologies. Working with experienced solar providers who understand both current capabilities and emerging technologies ensures your system remains adaptable to future innovations while maximizing return on investment.

The transition to industrial solar power systems represents a pivotal step toward sustainable and efficient manufacturing operations. By implementing solar-powered automation solutions, businesses can significantly reduce their operational costs while demonstrating environmental leadership in their respective industries. The evidence is compelling: companies that have adopted industrial solar systems report average energy cost reductions of 40-60% within the first year, along with enhanced operational reliability and reduced dependency on grid power.

The benefits extend beyond immediate cost savings. Industrial solar installations provide long-term price stability, protection against rising utility rates, and valuable tax incentives that improve the overall return on investment. Moreover, the integration of solar power with industrial automation systems creates a synergistic effect, optimizing energy consumption patterns and maximizing production efficiency.

As global markets increasingly prioritize sustainable manufacturing practices, industrial solar power systems offer a competitive advantage that cannot be ignored. The technology is mature, the economics are favorable, and the environmental benefits are undeniable. For business leaders and facility managers considering this transition, the time to act is now. With numerous financing options available and continuing technological improvements, industrial solar power systems represent not just an environmental choice, but a smart business decision that will deliver returns for decades to come.

Take the first step toward energy independence and sustainable operations by exploring how solar power can transform your industrial facility.