The Department of Energy’s Hydrogen Roadmap represents a transformative $9.5 billion initiative that’s reshaping America’s energy landscape, marking the most significant federal investment in hydrogen infrastructure to date. This comprehensive strategy aims to reduce clean hydrogen production costs to $1 per kilogram by 2031, while building a nationwide network of hydrogen hubs and accelerating commercial adoption across industrial sectors.

As global markets pivot toward sustainable energy solutions, the DOE’s hydrogen roadmap emerges as a critical blueprint for decarbonizing hard-to-abate sectors, including steel production, heavy transportation, and chemical manufacturing. Through strategic public-private partnerships and targeted technological innovations, this initiative promises to create over 100,000 clean energy jobs while significantly reducing carbon emissions across the industrial spectrum.

The roadmap’s multi-phased approach combines immediate infrastructure development with long-term research and development goals, establishing clear metrics for success and accountability. For business leaders and industry stakeholders, this framework provides unprecedented opportunities to participate in the emerging hydrogen economy while securing competitive advantages in an increasingly carbon-conscious marketplace.

The Strategic Vision Behind DOE’s Hydrogen Initiative

Key Milestones and Targets

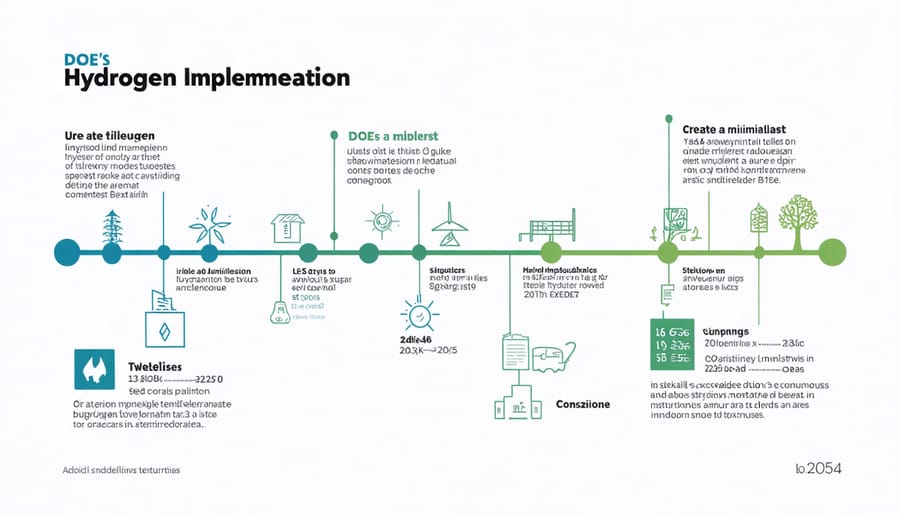

The DOE’s hydrogen roadmap outlines ambitious targets across multiple timeframes, with key milestones set for 2025, 2030, and 2050. By 2025, the plan aims to establish at least 50 hydrogen hubs nationwide, supporting the initial deployment of hydrogen infrastructure in key industrial clusters. The 2030 objectives include reducing clean hydrogen production costs to $1 per kilogram, establishing a network of 1,000 hydrogen fueling stations, and achieving 10% hydrogen integration in hard-to-decarbonize sectors.

Looking further ahead to 2050, the roadmap targets complete integration of hydrogen infrastructure across all major industrial corridors, with hydrogen meeting 20% of total energy demand. Specific industrial milestones include converting 95% of steel production to hydrogen-based processes and implementing hydrogen fuel cells in 30% of heavy-duty transportation.

The plan also establishes intermediary targets for manufacturing capacity, calling for domestic production of 10 million metric tons of clean hydrogen annually by 2030, and 50 million metric tons by 2050. These targets align with the broader goal of achieving net-zero emissions while maintaining economic competitiveness in the global hydrogen market.

Investment and Funding Framework

The DOE’s hydrogen roadmap is backed by substantial financial commitments, with $9.5 billion allocated through the Infrastructure Investment and Jobs Act. This includes $8 billion specifically designated for Regional Clean Hydrogen Hubs, $1 billion for clean hydrogen electrolysis research, and $500 million for manufacturing and recycling initiatives.

The framework establishes multiple funding mechanisms, including competitive grants, cost-sharing agreements, and public-private partnerships. Private sector investments are incentivized through production tax credits of up to $3 per kilogram of clean hydrogen, depending on carbon intensity levels. Additional support comes through loan guarantees and direct federal procurement commitments.

State-level matching funds and regional economic development initiatives complement federal funding, creating a comprehensive financial ecosystem for hydrogen infrastructure development. The DOE has also implemented a streamlined application process for funding opportunities, with dedicated support for small businesses and disadvantaged communities.

Investment priorities focus on scaling production capacity, expanding distribution infrastructure, and advancing technological innovations that reduce costs across the hydrogen value chain.

Infrastructure Development and Implementation

Production Facilities and Hubs

The DOE’s hydrogen roadmap outlines an ambitious network of regional hydrogen hubs designed to accelerate the adoption of hydrogen technologies across the United States. These strategic locations will house clean hydrogen production facilities capable of generating hydrogen through various methods, including electrolysis powered by renewable energy sources.

The plan identifies seven initial hydrogen hubs, strategically positioned across different geographical regions to maximize distribution efficiency and minimize transportation costs. Each hub is designed to leverage local resources and existing infrastructure while serving specific industrial clusters and transportation corridors.

Key features of these production facilities include:

– Scalable production capacity ranging from 50 to 100 tonnes per day

– Integration with renewable energy sources such as solar and wind power

– Advanced storage and distribution infrastructure

– Co-location with major industrial users

– Connection to existing natural gas pipeline networks where feasible

The hubs will be developed in phases, with initial operations scheduled to begin by 2025. The DOE estimates these facilities will collectively produce approximately 50,000 tonnes of clean hydrogen annually by 2030, supporting both regional and national decarbonization goals while creating thousands of clean energy jobs across the supply chain.

Distribution Networks

The DOE’s hydrogen roadmap outlines an extensive plan for developing robust distribution networks essential for the widespread adoption of hydrogen energy. The strategy encompasses both pipeline infrastructure and transportation methods, with a projected investment of $9-11 billion by 2030 to establish regional hydrogen hubs across the United States.

Critical components include the conversion of existing natural gas pipelines for hydrogen transport and the development of new, dedicated hydrogen pipelines. The plan addresses infrastructure safety considerations through advanced materials selection and monitoring systems to prevent hydrogen embrittlement and ensure reliable distribution.

The roadmap prioritizes strategic corridor development, connecting major industrial centers with hydrogen production facilities. These corridors will feature strategically placed compression stations, storage facilities, and dispensing terminals to maintain consistent supply chains. Initial deployment focuses on high-demand industrial clusters, gradually expanding to support transportation and commercial applications.

Storage solutions incorporate both underground caverns for large-scale storage and above-ground facilities for regional distribution. The plan emphasizes redundancy and reliability, ensuring multiple supply routes and storage options to maintain consistent availability. This comprehensive approach aims to create a resilient distribution network capable of supporting the projected hydrogen demand growth through 2050.

Commercial Applications and Market Integration

Industry Adoption Pathways

The DOE’s hydrogen roadmap identifies several key sectors for initial hydrogen technology deployment, prioritizing industries where decarbonization is challenging through conventional means. Heavy-duty transportation, including long-haul trucking and maritime shipping, represents a primary focus due to the limitations of battery-electric alternatives. Industrial processes, particularly in steel manufacturing and chemical production, are targeted for early commercial hydrogen applications, leveraging existing infrastructure and immediate carbon reduction potential.

Energy storage and grid stabilization emerge as another crucial adoption pathway, with hydrogen serving as a long-duration storage medium for renewable energy. The roadmap also emphasizes opportunities in building heating and industrial heat applications, where hydrogen can replace natural gas in existing systems with minimal modifications.

Regional hydrogen hubs are being developed to concentrate these early adopters, creating economies of scale and shared infrastructure. These hubs strategically connect hydrogen producers with end-users, reducing transportation costs and accelerating market development. The approach focuses on establishing sustainable demand while simultaneously scaling production capacity, ensuring long-term market viability and investment returns.

Business Integration Models

The DOE Hydrogen Roadmap outlines several business integration models to facilitate widespread hydrogen adoption across various sectors. These models include public-private partnerships, consortiums, and direct investment opportunities that enable organizations to participate in the hydrogen economy while managing risks and maximizing returns.

Key implementation frameworks include the Hub-and-Spoke model, where central hydrogen production facilities serve multiple end-users through distributed networks, and the Vertical Integration approach, where companies control multiple stages of the hydrogen value chain. The roadmap also promotes the Development Partnership model, encouraging collaboration between technology providers, infrastructure developers, and end-users.

For smaller businesses, the roadmap suggests a phased approach starting with pilot projects and gradually scaling up operations. This includes options for equipment leasing, shared infrastructure arrangements, and performance contracting to minimize initial capital requirements.

The integration models emphasize flexibility and adaptability, allowing businesses to choose entry points that align with their capabilities and resources. Financial mechanisms such as tax incentives, grants, and carbon credits are integrated into these models to improve project viability and accelerate market adoption.

To ensure successful implementation, the roadmap recommends establishing clear metrics for performance monitoring, risk assessment protocols, and standardized contractual frameworks for business partnerships.

Environmental Impact and Sustainability Metrics

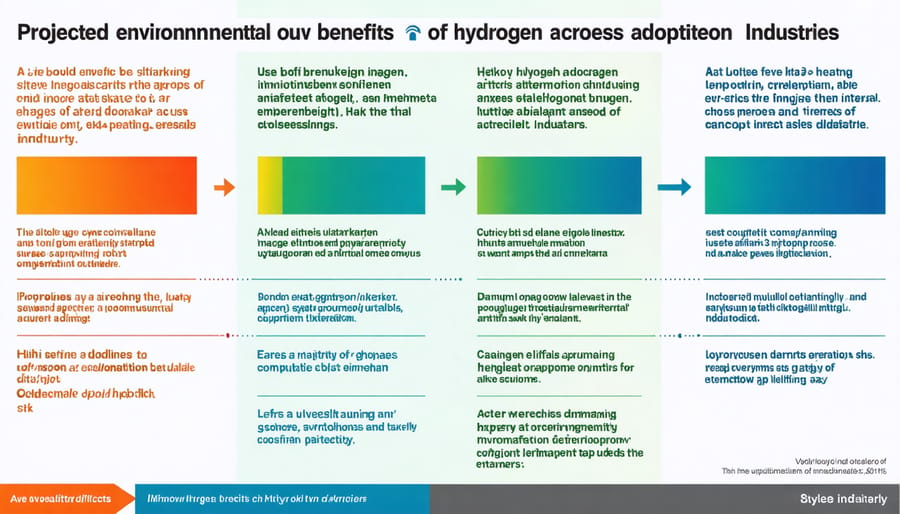

The DOE Hydrogen Roadmap places significant emphasis on environmental sustainability metrics, establishing clear benchmarks for reducing greenhouse gas emissions through hydrogen adoption. Initial environmental impact assessment data indicates that green hydrogen production could reduce carbon emissions by up to 90% compared to traditional fossil fuel-based processes.

Key sustainability metrics outlined in the roadmap include carbon intensity measurements, water consumption rates, and land use efficiency. The plan targets a 50% reduction in hydrogen production emissions by 2030, with complete carbon neutrality projected by 2050. Water consumption metrics are particularly crucial, as the roadmap emphasizes the implementation of advanced electrolysis technologies that can reduce water usage by 35% compared to current methods.

The roadmap also establishes comprehensive lifecycle analysis requirements for hydrogen infrastructure projects. These assessments evaluate environmental impacts from production through end-use, including transportation and storage considerations. Performance indicators track renewable energy integration, measuring the percentage of green electricity used in hydrogen production processes.

Resource efficiency metrics focus on optimizing production yields while minimizing waste. The roadmap sets specific targets for material recovery and recycling rates, particularly for critical minerals used in electrolyzers and fuel cells. Additionally, air quality improvements are quantified through reduced NOx and particulate matter emissions, with projected benefits for urban and industrial areas.

These sustainability metrics are designed to align with international climate commitments while providing measurable benchmarks for industry stakeholders to track progress and ensure accountability in the transition to clean hydrogen energy systems.

The DOE Hydrogen Roadmap represents a transformative framework that positions hydrogen as a cornerstone of America’s clean energy future. By establishing clear milestones and actionable strategies, the roadmap provides stakeholders with a viable path toward widespread hydrogen adoption across multiple sectors. For industry leaders and facility managers, the implementation of these guidelines offers significant opportunities for cost reduction, operational efficiency, and environmental compliance.

Moving forward, success depends on coordinated action from all stakeholders. Businesses should begin evaluating their hydrogen integration potential and developing implementation strategies aligned with the roadmap’s timeline. Government officials must focus on creating supportive policy frameworks and funding mechanisms to accelerate adoption. Meanwhile, industry leaders should prioritize research and development efforts in key areas identified by the roadmap, particularly in storage technologies and infrastructure development.

The roadmap’s comprehensive approach, combining technical innovation with market development strategies, positions the United States to become a global leader in hydrogen technology. By following this strategic framework, stakeholders can contribute to building a robust hydrogen economy while achieving their sustainability goals and maintaining competitive advantages in an evolving energy landscape.