Thermoelectric energy harvesting stands at the forefront of sustainable industrial innovation, transforming waste heat into valuable electrical power. By capturing temperature differentials across manufacturing processes, HVAC systems, and industrial equipment, businesses can significantly reduce operational costs while advancing their sustainability goals. This emerging technology, working alongside established energy storage technologies, offers a compelling solution for organizations seeking to optimize their energy efficiency without disrupting existing operations.

Recent advancements in thermoelectric materials and system design have pushed conversion efficiencies beyond 10%, making this technology increasingly viable for commercial applications. From automotive manufacturing to data centers, thermoelectric harvesting systems are delivering measurable returns on investment while contributing to corporate environmental targets. As global energy costs continue to rise and sustainability regulations tighten, forward-thinking businesses are recognizing thermoelectric harvesting as a strategic asset in their energy management portfolio.

How Thermoelectric Energy Harvesting Works

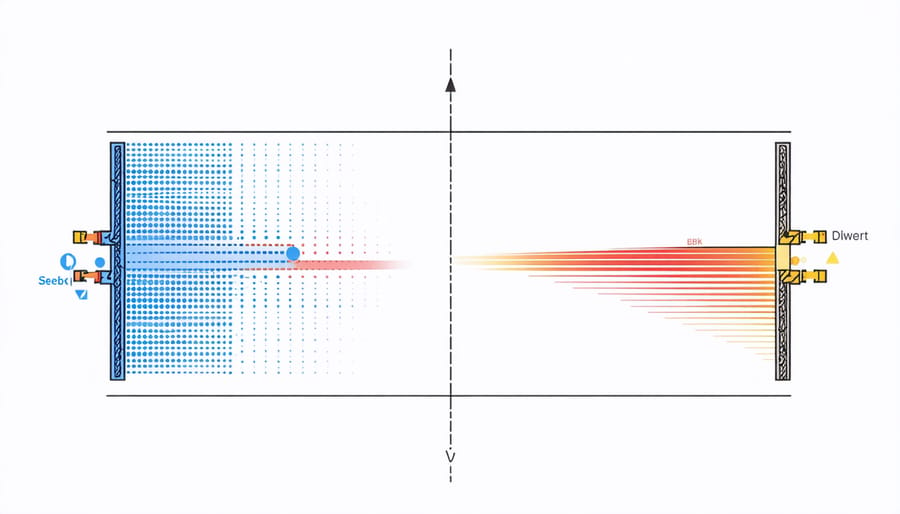

The Seebeck Effect Explained

The Seebeck effect, discovered by Thomas Seebeck in 1821, forms the fundamental principle behind thermoelectric energy generation. This phenomenon occurs when two different conducting materials are joined at their ends and exposed to different temperatures, creating an electrical voltage. The greater the temperature difference between the hot and cold sides, the higher the voltage produced.

In practical applications, this effect is harnessed through thermoelectric generators (TEGs), which consist of multiple thermocouples connected in series. When one side of the TEG is heated while the other remains cool, the temperature gradient causes electrons to flow from the hot side to the cold side, generating usable electrical current.

The efficiency of this energy conversion depends primarily on the temperature differential and the properties of the materials used. Modern thermoelectric materials can achieve conversion efficiencies of 5-8% in industrial settings, making them viable for waste heat recovery applications. This direct conversion of heat to electricity, without moving parts, offers remarkable reliability and minimal maintenance requirements, making it particularly attractive for industrial waste heat recovery and remote power generation applications.

Key Components and Materials

Thermoelectric energy harvesting systems rely on several key components to effectively convert temperature differences into usable electrical power. The foundation of these systems is the thermoelectric module, typically constructed from semiconductor materials such as bismuth telluride, lead telluride, or silicon-germanium alloys. These materials are selected for their high Seebeck coefficient and optimal electrical conductivity.

The hot-side heat exchanger and cold-side heat sink are crucial elements that maintain the temperature differential necessary for power generation. High-performance thermal interface materials ensure efficient heat transfer between components, while electrical conductors and connectors facilitate power transmission to the intended application.

Power management circuits, including DC-DC converters and voltage regulators, optimize the output for practical use. These components are often supplemented with energy storage solutions like supercapacitors or small batteries to maintain consistent power delivery during fluctuating temperature conditions.

Modern thermoelectric systems also incorporate smart monitoring sensors and control systems to maximize efficiency and protect components from thermal stress, ensuring long-term reliability and optimal performance in commercial applications.

Commercial Applications and Benefits

Industrial Heat Recovery

Industrial facilities generate substantial amounts of waste heat during their manufacturing processes, presenting a significant opportunity for energy recovery through thermoelectric systems. By installing thermoelectric generators (TEGs) at key heat-intensive points in the production line, facilities can convert previously wasted thermal energy into useful electricity.

A typical manufacturing plant can recover between 5-15% of its waste heat through strategic TEG placement. Common implementation areas include furnaces, kilns, steam systems, and exhaust stacks, where temperature differentials are highest. For example, a steel manufacturing facility in Germany implemented TEG systems on their blast furnaces, achieving annual energy savings of €280,000 while reducing CO2 emissions by 1,200 tons.

The recovered energy can power auxiliary systems, such as lighting, sensors, or control equipment, reducing the facility’s overall grid dependency. This self-sustaining approach is particularly valuable in remote locations or areas with unreliable power supply. The modular nature of TEG systems allows for scalable implementation, enabling facilities to start with pilot projects and expand based on proven results.

Beyond direct energy savings, industrial heat recovery through thermoelectric systems contributes to environmental compliance and can qualify for government incentives. Many facilities report payback periods of 2-4 years, with ongoing benefits including reduced operational costs and enhanced sustainability metrics.

Building Energy Management

Building Energy Management Systems (BEMS) are increasingly incorporating thermoelectric energy harvesting technologies to enhance efficiency and reduce operational costs. These systems capture waste heat from HVAC equipment, data centers, and industrial processes, converting it into usable electricity that can supplement building power needs. When integrated with smart energy distribution systems, thermoelectric generators can provide a sustainable power source for low-energy applications such as wireless sensors, monitoring equipment, and building automation systems.

Leading commercial facilities have reported energy savings of 15-25% after implementing thermoelectric harvesting solutions in their HVAC systems. For example, a major office complex in Singapore achieved annual energy cost reductions of $75,000 by installing thermoelectric generators on their cooling towers and air handling units.

The technology proves particularly valuable in large commercial buildings where waste heat is abundant. Modern thermoelectric systems can power wireless sensor networks that monitor temperature, humidity, and occupancy levels, eliminating the need for battery replacement and reducing maintenance costs. This self-sustaining approach to building management aligns with green building certifications like LEED and BREEAM, while providing facility managers with reliable, maintenance-free power solutions for their building automation needs.

Integration costs have decreased significantly in recent years, making thermoelectric harvesting an increasingly attractive investment for facility managers seeking to optimize their energy infrastructure and reduce operational expenses.

Cost-Benefit Analysis

The implementation of thermoelectric energy harvesting systems presents a compelling financial case when analyzed over their operational lifetime. Initial installation costs typically range from $2,000 to $10,000 per kilowatt capacity, depending on the scale and complexity of the system. However, these systems can generate significant returns through energy savings and reduced maintenance requirements.

A typical industrial-scale thermoelectric installation can achieve payback periods of 3-5 years, with ROI rates ranging from 15% to 25% annually. For example, a manufacturing facility implementing a 50kW thermoelectric system reported annual energy savings of $45,000, with additional maintenance cost reductions of $12,000 per year.

The cost-benefit equation becomes even more favorable when considering government incentives and carbon credits. Many jurisdictions offer tax benefits and grants covering up to 30% of the initial investment. Additionally, the long operational life of thermoelectric systems (15-20 years) ensures sustained benefits with minimal degradation in performance.

When factoring in rising energy costs, the financial advantages become more pronounced. Analysis shows that facilities implementing thermoelectric harvesting systems can reduce their energy expenditure by 8-12% annually, with some high-waste-heat industries achieving savings of up to 20%. The absence of moving parts also translates to maintenance costs that are 60% lower than traditional power generation systems.

Integration with Solar Solutions

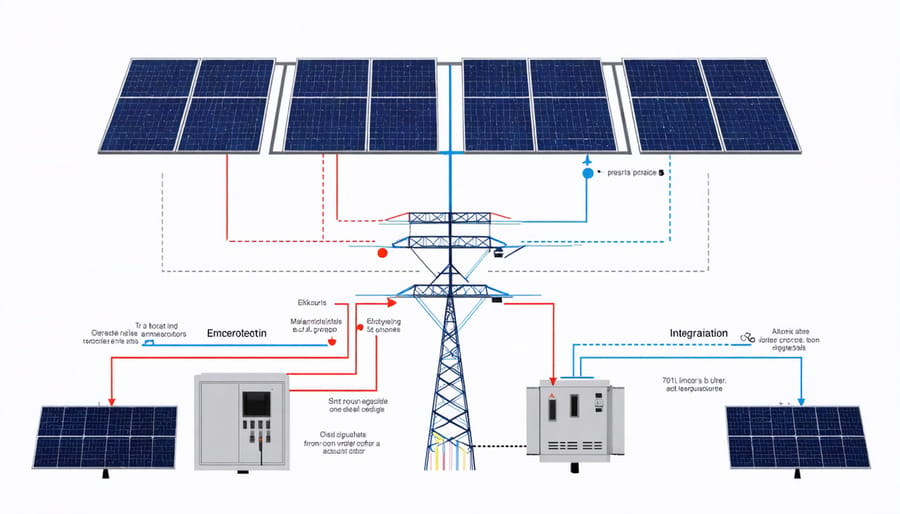

Hybrid Energy Systems

The integration of thermoelectric generators (TEGs) with solar photovoltaic systems represents one of the most promising advanced energy solutions in today’s market. These hybrid systems capitalize on both solar radiation and waste heat, significantly improving overall energy conversion efficiency and system reliability.

In practical applications, thermoelectric modules can be mounted on the rear surface of solar panels, where they harvest waste heat that would otherwise be lost. This arrangement serves two purposes: it generates additional electricity from the temperature differential and helps cool the solar panels, which typically operate more efficiently at lower temperatures.

Commercial installations have demonstrated energy yield improvements of 8-15% when compared to standalone solar systems. For example, a manufacturing facility in Stuttgart, Germany, implemented this hybrid approach in 2022 and reported a 12% increase in total power output while reducing their cooling costs by 20%.

The scalability of these hybrid systems makes them particularly attractive for industrial applications. Facilities can start with a pilot project and gradually expand based on performance data and ROI metrics. The complementary nature of these technologies also provides more consistent power generation throughout the day, reducing dependence on battery storage systems and grid power during periods of low solar radiation.

Enhanced Energy Efficiency

Thermoelectric energy harvesting systems demonstrate remarkable synergistic benefits when integrated with existing energy infrastructure, leading to enhanced overall system performance. By implementing advanced efficient energy management strategies, organizations can maximize the potential of waste heat recovery while optimizing their primary energy consumption.

The combination of thermoelectric generators with conventional heating and cooling systems creates a multiplicative effect on energy efficiency. For instance, industrial facilities implementing these systems have reported energy savings of up to 15-20% beyond their initial projections, as the recovered energy supplements primary power sources during peak demand periods.

These efficiency gains are particularly notable in manufacturing environments where waste heat is abundant. The captured energy can be redirected to power auxiliary systems, such as monitoring equipment, sensors, or lighting, reducing the load on the main power supply. This cascading benefit extends to reduced cooling requirements, as waste heat is converted to useful energy rather than requiring additional energy expenditure for heat removal.

Furthermore, the integration of thermoelectric systems with existing renewable energy infrastructure creates a more resilient and sustainable energy ecosystem. This complementary approach ensures consistent power availability while minimizing energy waste, ultimately contributing to improved operational efficiency and reduced environmental impact.

Implementation Success Stories

Several notable implementations of thermoelectric energy harvesting demonstrate the technology’s practical potential across various industries. BMW’s groundbreaking initiative in 2018 captured waste heat from vehicle exhaust systems, generating up to 750W of additional power and improving fuel efficiency by 3%. This successful application has since inspired other automotive manufacturers to explore similar solutions.

In the industrial sector, a steel manufacturing plant in Sweden implemented a large-scale thermoelectric system in 2020 that recovers waste heat from their smelting operations. The installation generates approximately 2.1 MW of electricity annually, resulting in a 15% reduction in overall energy costs and an estimated ROI period of just four years.

The telecommunications industry has also embraced thermoelectric energy harvesting. Vodafone’s pilot program in rural India uses thermoelectric generators to power remote cell towers, converting heat from solar radiation into electricity. This implementation has reduced diesel generator usage by 60% and decreased maintenance costs by 40%, while improving network reliability in remote areas.

A noteworthy example in the maritime sector comes from the Norwegian shipping company Wilhelmsen, which installed thermoelectric generators on their cargo vessels in 2021. The system harvests heat from engine exhaust, providing supplementary power for onboard electronics and reducing fuel consumption by 2.5% across their fleet.

The semiconductor industry demonstrates another successful application, with Intel’s manufacturing facility in Arizona implementing a thermoelectric system that converts process heat into usable electricity. This installation generates 1.5 MW of power annually and has reduced the facility’s grid dependency by 8%.

These success stories share common elements: careful system design, strategic placement of thermoelectric modules, and integration with existing infrastructure. The implementations typically show ROI periods ranging from 3-6 years, with additional benefits including reduced carbon emissions, lower maintenance requirements, and improved operational efficiency.

Companies considering thermoelectric energy harvesting can learn from these experiences, particularly regarding optimal placement of generators, scaling considerations, and integration with existing power systems. The success of these installations demonstrates that thermoelectric energy harvesting is not just theoretically promising but practically viable across diverse industrial applications.

Thermoelectric energy harvesting presents a compelling opportunity for businesses seeking to enhance their energy efficiency and sustainability initiatives. As technology continues to advance and costs decrease, implementing thermoelectric solutions becomes increasingly viable for commercial applications. Organizations can start by identifying waste heat sources within their facilities and conducting feasibility studies to determine potential ROI. The next practical steps include consulting with energy specialists, piloting small-scale implementations, and developing integration strategies with existing systems. With proper planning and execution, thermoelectric energy harvesting can contribute significantly to both environmental goals and operational cost reduction. As the technology matures, early adopters will be well-positioned to leverage these solutions for competitive advantage and environmental stewardship.